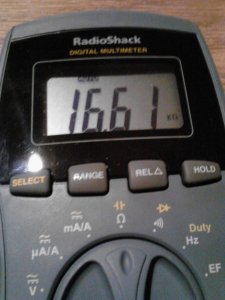

To test a capacitor, you can use the capacitance setting of your DMM. However, most such DMM's only test for capacitance and does not measure ESR. You can also check using the ohms setting. It should not be shorted. Most likely, it will start counting up towards infinity, and the rate depends upon the capacitance. However, like I said, that 4700uf cap is merely a ripple filter anyhow and in my view, it's not even worth testing since it's doubtful related to your issue. You've already ordered it so just install it and be done with it. No point doing a recap and leaving an old one in.

When testing resistors, you should not be using the tone feature of the DMM, which is more intended for a continuity test. Resistors have........... resistance, which depending upon it's value, will result in the meter emitting a tone, or not. Depends upon the resistance threshold of your particular meter.

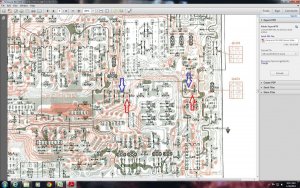

Speaking of continuity testing... you are testing traces, not continuity THROUGH resistors unless you also add the expected values of the inline resistors and include those into your readings. Also, if you can find a ground rail, you will notice while studying the schematic that many capacitors will terminate at ground. In general, you can expect the (-) lead to terminate at ground. You can clip one end of your dmm lead to a ground rail and probe all the caps that should terminate at ground. If a cap is supposed to terminate at ground but results in high resistance (or open), then you have a problem and need to investigate further.