Fixing a legend.....

- Thread starter blu_fuz

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

baddboybill

Boomus Fidelis

I remember looking at the main power board and there weren't any caps on it that I could re-call. Just looked at it again and there isn't any electrolytic capacitors on it.

Tried on batteries after sanding the contacts and it is the same result, just the constant motorboating.

The big black cap on the main board I didn't replace is a 4700uf 25V. I'm going to get that ordered so I can try that next. I don't want to swap caps on the tuner board because it might throw off the tuner, right?

Either way, I'm glad I have all the main caps replaced so when the problem is figured out this thing will JAM!

Tried on batteries after sanding the contacts and it is the same result, just the constant motorboating.

The big black cap on the main board I didn't replace is a 4700uf 25V. I'm going to get that ordered so I can try that next. I don't want to swap caps on the tuner board because it might throw off the tuner, right?

Either way, I'm glad I have all the main caps replaced so when the problem is figured out this thing will JAM!

Thanks Greg - every little bit of support helps to motivate on getting this working again. It was tedious work but I am 100% sure every cap I replaced is installed in the correct polarity and rating. I want to thank Norm (superpooper) for some behind the scenes tips for a re-cap of this size. I appreciate all the help from everyone.

I ordered the 4700/25 cap off epay, so maybe it will be here by tuesday. I'll replace that cap and look over the ICs again for any damage I might have missed.

PS, any of you 5350 owners know where the other end of this brown wire goes????

I ordered the 4700/25 cap off epay, so maybe it will be here by tuesday. I'll replace that cap and look over the ICs again for any damage I might have missed.

PS, any of you 5350 owners know where the other end of this brown wire goes????

BoomboxLover48

Boomus Fidelis

I believe that is a test lead!

I could be wrong!

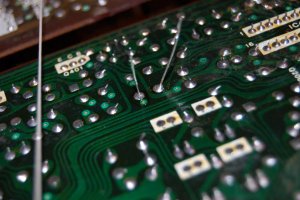

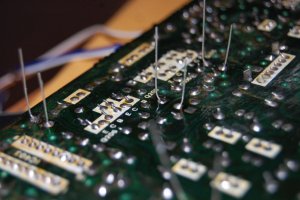

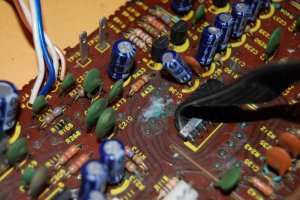

The leads of R404, R424 (low value resistor built into the PC board) got lots of oxidation that looks from battery leak.

So also there is (basic oxide of Cu) deposits at C427

This box had a very bad battery leak.

Good luck Joe!

I could be wrong!

The leads of R404, R424 (low value resistor built into the PC board) got lots of oxidation that looks from battery leak.

So also there is (basic oxide of Cu) deposits at C427

This box had a very bad battery leak.

Good luck Joe!

Northerner

Boomus Fidelis

Wow some serious work going on here....pretty impressed...you deserve to get this one booming so keep up the good work!

So the brown wire might not need to go anywhere?BoomboxLover48 said:I believe that is a test lead!

I could be wrong!

The leads of R404, R424 (low value resistor built into the PC board) got lots of oxidation that looks from battery leak.

So also there is (basic oxide of Cu) deposits at C427

This box had a very bad battery leak.

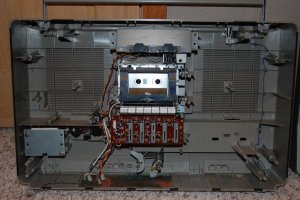

I think you are right that there was a battery leak. You can see the copper grounding plate is pretty green at the bottom of the rear case picture shown above. I was wondering where all this green oxidation might have come from:

BoomboxLover48

Boomus Fidelis

We need to clean all those deposits well or else it will keep on eating up the PC lines and leads.blu_fuz said:So the brown wire might not need to go anywhere?

I think you are right that there was a battery leak. You can see the copper grounding plate is pretty green at the bottom of the rear case picture shown above. I was wondering where all this green oxidation might have come from:

1-19-14 002.jpg

Alkaline batteries contain potassium hydroxide, a caustic agent that can cause respiratory, eye and skin irritation. In order to neutralize the leaked alkaline you will need a household acid like vinegar or lemon juice. A Q-tip or old tooth brush can help scrub the leakage from the electrical contacts. Always use household gloves and safety glass

Clean acid-based batteries with baking soda and a little bit of water on a Q-tip or old tooth brush. Never put water directly on the acid. Here I believe it is not an acid battery that has leaked.

BoomboxLover48

Boomus Fidelis

I would make a 50:50 blend of water to vinegar and use a Q-tip Joe! That is better. Toothbrush will spray it all over the place. We want to contain the debris to one area and not on any other components! Go in circular motion....and change the Q-tip to cleaner and better ones as you work on.blu_fuz said:So get into cleaning it with vinegar or lemon juice by q-tip and/or toothbrush?

It is acetic acid (vinegar) or citric acid (lemon juice may contain 5-6%) for the neutralization of KOH....

BoomboxLover48

Boomus Fidelis

Joe,

The large cap in the power supply is a filter capacitor and it's doubtful that it has anything to do with your motorboating. All it does is filter out the ripples in the supply rails. Does it do this on both AC and DC? If so, then for sure it has nothing to do with that one.

You have not wasted your efforts. Regardless of the issue, the recapping will definitely improve the sound performance and future reliability.

The electrolytic caps in the tuner can be changed if you like. They dry out and deteriorate just like all the other caps in your boombox. Fortunately, they usually do not affect tuner alignment since they are typically used as bypass caps or audio coupling caps. Keep in mind that older caps like that have as much as 20%+ tolerance. Any capacitor critical for tuner alignment needs to be greater precision variety. However, unless the problem only occurs during tuner operation, once again, it's likely not related. There are critical caps that you do not want to change in the tuner, but those are the ceramic and styrol and other similar caps. They would likely affect alignment or the oscillators if replaced. Another reason to avoid the tuner is that while handling the board in that location, it's very easy to distort the tuning coils. This can happen even if you are careful and mindful -- it's very easy to do since it's very hard to keep track of all 10 of your fingers during handling.

The corrossion issue is another matter. Motorboating can be related to bad caps but there is a relationship with the related resistance/capacitance in the circuit, either of which can shift. Because value shift is much more prevalent with aged electrolytic capacitors than the resistors, they are generally suspect before resistors are. Many PC boards back in the day had early double-sided designs, which are not very reliable. Todays boards have copper on both sides (and sometimes in between in layers too). Early boards had copper on one side and printed resistors or traces on the flip side. The "printed" conductors are notorious for failing or shifting. If I see corossion like that, especially in the areas where the top traces are, I'm whipping out my Fluke meter and needle probes to check for continuity and resistance. In fact, what I do is find the origin of a trace and follow it top/below and see if continuity is intact. Don't do short segmented checks unless your check on long bottom/top/botton traces shows an issue. Then you can try to narrow where the issue is. For example, you can check A-B, B-C, C-D, D-E, E-F. But for me, I'd much rather just check A-F and if continuity is good, then there's no point to check C-D, right? I would just use a horsehair applicator brush with some isopropyl to clean the green stuff. You can follow up with clear water if you like.

You also never mentioned detailed testing. Too often, I read "my boombox does this... what's the problem?" For a better analysis, it's much better if I read "The sound is like THIS in A mode but not B; It sounds bad through speakers and headphones but outputs a proper sound via line-out; it only occurs on A side; it happens on both AC and DC, etc. etc." Armed with these clues, we can certainly make a better analysis as these symptoms and clues helps to eliminate certain things (mean more time saved, and less wasted work). Do a complete and through check, even if you don't think it's related.

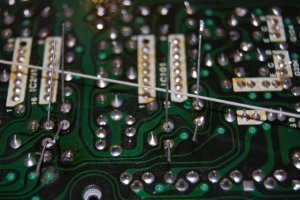

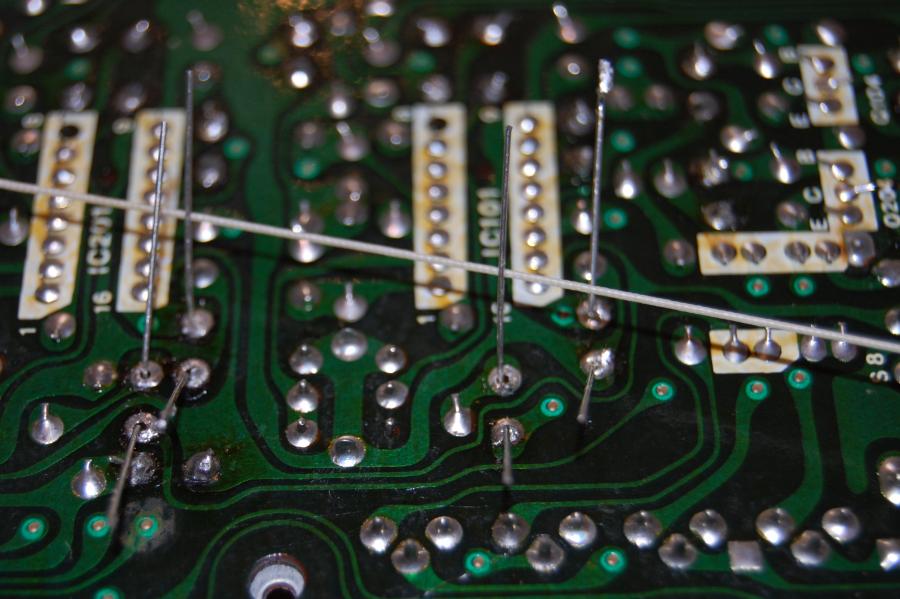

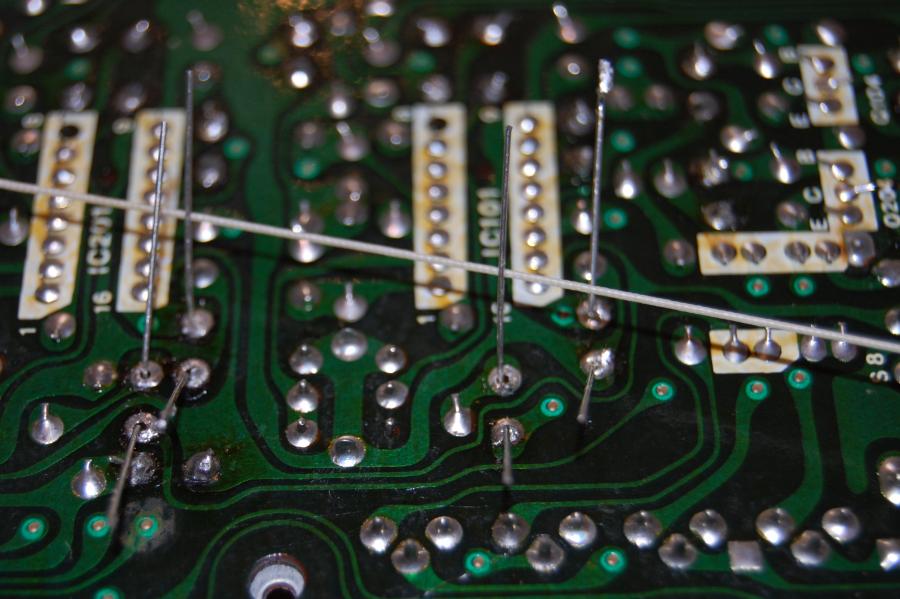

Last thing.... on at least 1 picture, I see new cap leads poorly soldered (or perhaps they were not completed yet). I presume you photographed it and touched up those pads after? If not, then you definitely want to check and ensure that all joints are soldered well.

Hope this helps.

The large cap in the power supply is a filter capacitor and it's doubtful that it has anything to do with your motorboating. All it does is filter out the ripples in the supply rails. Does it do this on both AC and DC? If so, then for sure it has nothing to do with that one.

You have not wasted your efforts. Regardless of the issue, the recapping will definitely improve the sound performance and future reliability.

The electrolytic caps in the tuner can be changed if you like. They dry out and deteriorate just like all the other caps in your boombox. Fortunately, they usually do not affect tuner alignment since they are typically used as bypass caps or audio coupling caps. Keep in mind that older caps like that have as much as 20%+ tolerance. Any capacitor critical for tuner alignment needs to be greater precision variety. However, unless the problem only occurs during tuner operation, once again, it's likely not related. There are critical caps that you do not want to change in the tuner, but those are the ceramic and styrol and other similar caps. They would likely affect alignment or the oscillators if replaced. Another reason to avoid the tuner is that while handling the board in that location, it's very easy to distort the tuning coils. This can happen even if you are careful and mindful -- it's very easy to do since it's very hard to keep track of all 10 of your fingers during handling.

The corrossion issue is another matter. Motorboating can be related to bad caps but there is a relationship with the related resistance/capacitance in the circuit, either of which can shift. Because value shift is much more prevalent with aged electrolytic capacitors than the resistors, they are generally suspect before resistors are. Many PC boards back in the day had early double-sided designs, which are not very reliable. Todays boards have copper on both sides (and sometimes in between in layers too). Early boards had copper on one side and printed resistors or traces on the flip side. The "printed" conductors are notorious for failing or shifting. If I see corossion like that, especially in the areas where the top traces are, I'm whipping out my Fluke meter and needle probes to check for continuity and resistance. In fact, what I do is find the origin of a trace and follow it top/below and see if continuity is intact. Don't do short segmented checks unless your check on long bottom/top/botton traces shows an issue. Then you can try to narrow where the issue is. For example, you can check A-B, B-C, C-D, D-E, E-F. But for me, I'd much rather just check A-F and if continuity is good, then there's no point to check C-D, right? I would just use a horsehair applicator brush with some isopropyl to clean the green stuff. You can follow up with clear water if you like.

You also never mentioned detailed testing. Too often, I read "my boombox does this... what's the problem?" For a better analysis, it's much better if I read "The sound is like THIS in A mode but not B; It sounds bad through speakers and headphones but outputs a proper sound via line-out; it only occurs on A side; it happens on both AC and DC, etc. etc." Armed with these clues, we can certainly make a better analysis as these symptoms and clues helps to eliminate certain things (mean more time saved, and less wasted work). Do a complete and through check, even if you don't think it's related.

Last thing.... on at least 1 picture, I see new cap leads poorly soldered (or perhaps they were not completed yet). I presume you photographed it and touched up those pads after? If not, then you definitely want to check and ensure that all joints are soldered well.

Hope this helps.

Yes Norm, this picture below I was showing that tuner string is directly over some areas you need to work in when replacing the caps. You can still do all the cap replacement work without removing the tuner string, BUT YOU MUST BE CAREFUL! If a hot solder iron hits that string it will melt through it so fast that it will be broke before you even realize you touched it.

PS, I did solder those pads after I took this picture .

.

I will get my multimeter out and find the origin of traces and follow it top/below and see if continuity is intact without just checking short segments of the circuit.

Here is what my hands-on tests were:

- with AC or DC, as soon as you flip the power switch to radio (no real audible music on radio), or aux-in, the motor boating starts and the VU meters go full tilt to the right and don't swing to any audio signal on radio (need to test line-in again to check VU functions)

- with a cassette loaded, as soon as I push any function of the cassette ie; play, FF, RW, REC, etc. the motor boating starts

- while playing a cassette the VU meters are still swinging to whatever music is on the cassette, but again no audible music is heard only the motor boating

-motor boating is even in both channels (L/R) and balance knob works

I will check the aux-in, line in, line out, and everything else maybe tonight after work and report back.

PS, I did solder those pads after I took this picture

.

.

I will get my multimeter out and find the origin of traces and follow it top/below and see if continuity is intact without just checking short segments of the circuit.

Here is what my hands-on tests were:

- with AC or DC, as soon as you flip the power switch to radio (no real audible music on radio), or aux-in, the motor boating starts and the VU meters go full tilt to the right and don't swing to any audio signal on radio (need to test line-in again to check VU functions)

- with a cassette loaded, as soon as I push any function of the cassette ie; play, FF, RW, REC, etc. the motor boating starts

- while playing a cassette the VU meters are still swinging to whatever music is on the cassette, but again no audible music is heard only the motor boating

-motor boating is even in both channels (L/R) and balance knob works

I will check the aux-in, line in, line out, and everything else maybe tonight after work and report back.

Joe, Wish I had access to my 5350 manual (I don't). However, it sounds like whatever is ailing your machine is common to both sides. Not sure if the 5350 uses BTL or SE amps but it might be related to the amps, or if the signals go through a signal processor (such as a dolby chip), or a dual preamp ID that is failing, that could cause it. If I were you, I would focus instead on those printed board traces. They go bad even without corossion. With the corrossion, that is highly suspect. If you find traces with no continuity, or high resistance, you should jump them. It could be tedious. I had boards that are like that. Hitachi and Toshiba are major offenders and even included resistors (and other components) that are simply printed. Worse yet, you can't solder to the printed traces so you'll need to find the nearest solder pad to tie to.

This is the only service manual I have access to for the 5350.

https://boomboxery.com/forum/index.php/files/file/65-national-panasonic-rx-5350-service-manual/

https://boomboxery.com/forum/index.php/files/file/65-national-panasonic-rx-5350-service-manual/

. I see your point though, we don't have any local repair places here

. I see your point though, we don't have any local repair places here  .

.