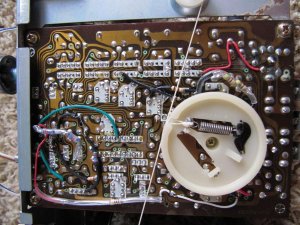

Because in that era, double sided copper boards were not common. However, due to the increasing circuitry complexity and required real estate to house all the circuitry, it was necessary to design a board that way for space reasons. Otherwise, the boards would be 50% or more larger and resemble the Aiwa and Sanyo boards with a charlottes web of wired jumpers all over the place. Backseat driving the engineering of a product 35-40 years after it has long passed it's useful design life is easy to do now. And sure enough, a bulletproof board could be designed today using double (or more) copper sides for far less money. But back then, they didn't exist in mass manufacturing. That was the technology then, and technology has improved today. In fact, with the advent of SMD, components don't even need to have holes drilled onto the boards anymore and each side can truly be designed independantly without having to worry about a hole/pad to mount a component from the opposite side. To see how far along we've come, one only needs to look at the modular design of the JVC kabooms. Every board is designed with almost no jumpers and to me, a piece of art. Even the front panel boards are connected to the inside boards via only a mechanical connection that takes place when the front and back halves are mated together. No wires and connectors at all. Anyhow, 1-year warranty, lasted 30 years already.... what's the problem?