M70 Clutch Assembly

- Thread starter Mikey

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Transistorized

Member (SA)

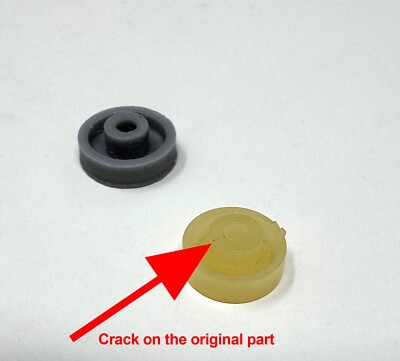

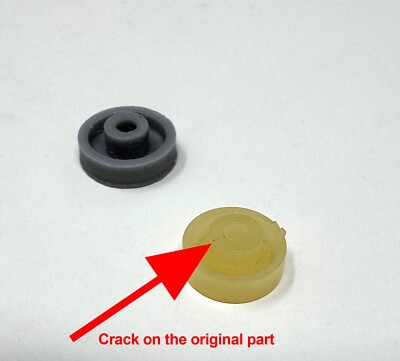

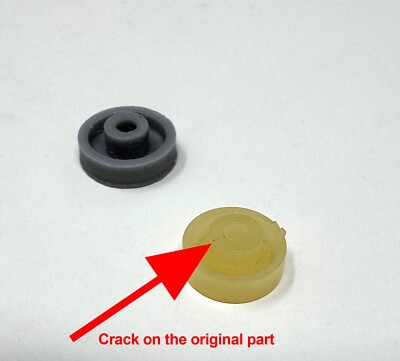

This is a common problem with this style clutch. The plastic shrinks and splits under its own tension. I've been fortunate enough to not have this happen yet, but this will eventually be in all M70's future.

JVC RC-M70 / M71 / M75 FF clutch plate/cap. Rewind & Fast Forward issue repair | eBay

Find many great new & used options and get the best deals for JVC RC-M70 / M71 / M75 FF clutch plate/cap. Rewind & Fast Forward issue repair at the best online prices at eBay! Free shipping for many products!

www.ebay.ca

Figured as much. Thanks for the link. Is this you? Someone you know? Random search?This is a common problem with this style clutch. The plastic shrinks and splits under its own tension. I've been fortunate enough to not have this happen yet, but this will eventually be in all M70's future.

JVC RC-M70 / M71 / M75 FF clutch plate/cap. Rewind & Fast Forward issue repair | eBay

Find many great new & used options and get the best deals for JVC RC-M70 / M71 / M75 FF clutch plate/cap. Rewind & Fast Forward issue repair at the best online prices at eBay! Free shipping for many products!www.ebay.ca

Transistorized

Member (SA)

This is just a search I performed. There are members here that are well versed in 3D design such as Caution, but I am not that talentedFigured as much. Thanks for the link. Is this you? Someone you know? Random search?

Tinman

Member (SA)

What did you do to replace them?Yep, both of the ones I owned had this problem.

Tinman

Member (SA)

It was years ago so I don't think anybody had replacement ones available so I glued them on.What did you do to replace them?

I can't say how long they lasted but it worked for as long as I had them.

BoomboxLover48

Boomus Fidelis

Assorted gears work well!

Basically, all you need is a plastic washer with the same hole size to push in and lock the whole clutch assembly in place.

It is easy to find a small gear with the same hole dimension.

Basically, all you need is a plastic washer with the same hole size to push in and lock the whole clutch assembly in place.

It is easy to find a small gear with the same hole dimension.

Last edited:

BoomboxLover48

Boomus Fidelis

I bought assorted gears from Ebay and found one that can be used to lock the clutch assembly. That worked so well.

Last edited:

For the cost of that 3D printed one, why even bother to give this another thought. It's really not worth the effort to measure and fuss with rigging something up.

Transistorized

Member (SA)

You have to practically blow this thing entirely apart to get to the clutch. It would suck to have to go back in because it failed again.For the cost of that 3D printed one, why even bother to give this another thought. It's really not worth the effort to measure and fuss with rigging something up.

Which does bring up a complaint that I have with the M70, aside from the known issue with the sliders. Fortunately those are easy to get to and remove for repair but I digress.

This radio is the only box I own that I absolutely make sure the tape speed and transport is right with a day or two of playback before I put it back together. The reason is, I don't want to have to remove the chassis again for adjustment or repair. It isn't too hard, it's just more than I feel you should have to do. Especially when it comes to adjusting the tape speed. Unless it's the model with pitch control, it's almost worth drilling a tiny hole next to the counter wheel on the front and putting a M70 decal over it.

I'm sure the idea was that you shouldn't have to touch the speed after it's adjusted correctly. In those days, that made sense. However, the crappy or NOS belts that are past their prime today, tend to stretch after a few hours of playback which would make a convenient speed adjustment welcome.

Last edited:

BoomboxLover48

Boomus Fidelis

I've mentioned about the assorted gears before. You can find several small gears from it with the same hole size so you can friction fit one there.All I want to do is replace the part and move on. Need to stick something in there before I close it up.

This is a bad design where JVC put a friction fit plastic washer to hold the clutch assembly in place where a E clip lock along with a washer was needed.

Plastic type used for this need hardened and cracked. Polypropylene could have worked better but the type of plastic used can contain other polyolefins or plasticizers.

Last edited: