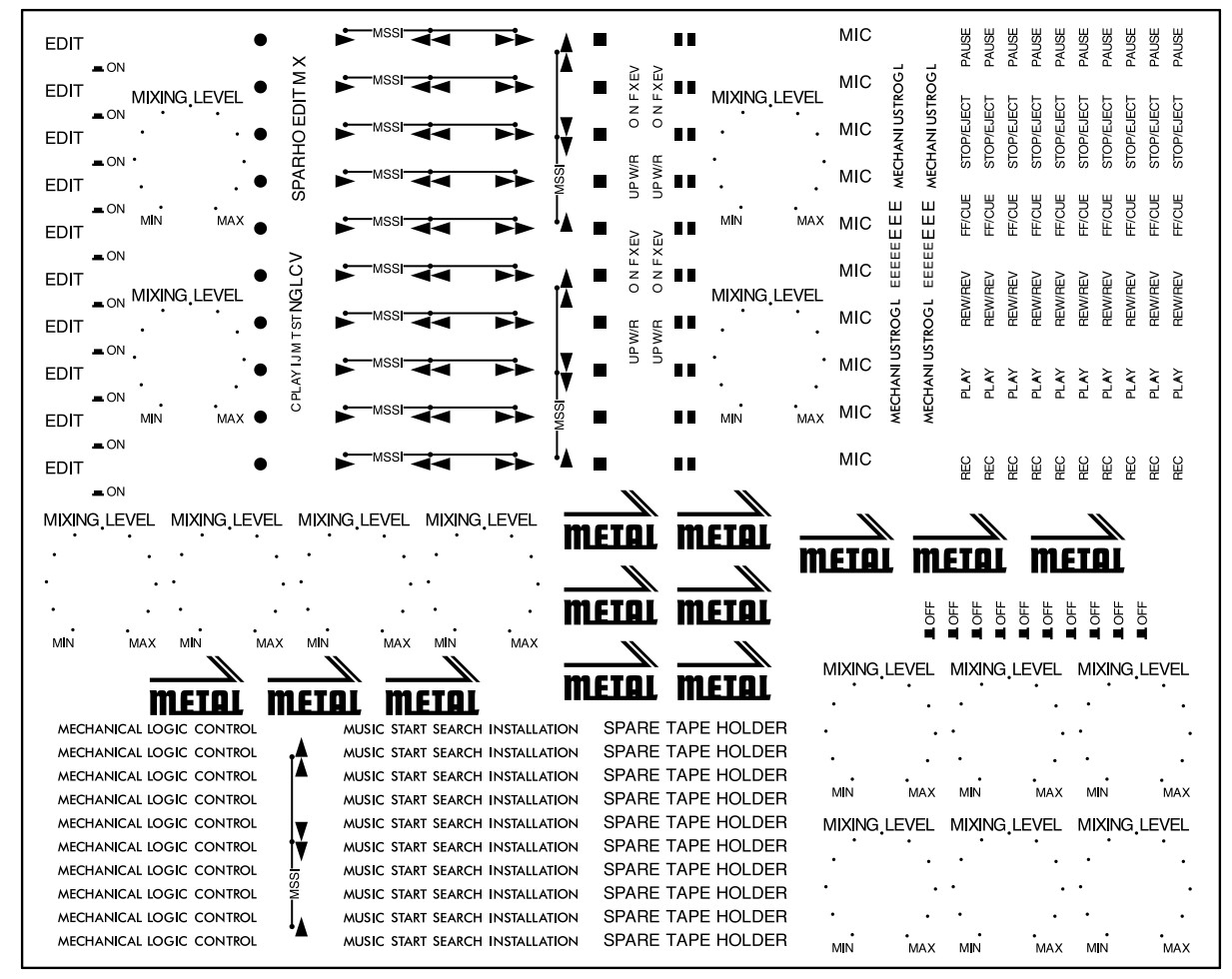

I got the dry transfers for the other two pieces!

My first attempt at bending the door piece taught me that bending the little tabs I made kept the sides from bending straight, so I ended up with a pillowy looking bend. Boo.

So, I ground those off for the second one, but I forgot that you must compensate for the thickness of the metal in your scribe line, so I had to go the opposite direction on the other side to balance it out...

It lines up and would work fine, but when you look closer, I had peeled off the protective plastic too soon and the bending brake scuffed it. So now I know what not to do for the next batch

I tried to bend one of the deck trims but it popped out of the brake half-bent, so I'm going to take some advice from a sheet metal forum and have them re-made with a bit more extra material on that edge so I have something to grab. With the thicker metal I'll have to go about halfway into the bend for the right depth.

Super easy to work with though and honest as they come, he made them right away no charge.

Super easy to work with though and honest as they come, he made them right away no charge.