C-100F control panel trim spec

- Thread starter caution

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

To get 'er done I used a few things. First I bought a scanner at Goodwill for $7 and hooked it up to an old XP box (no newer drivers!!) and scanned the trims.

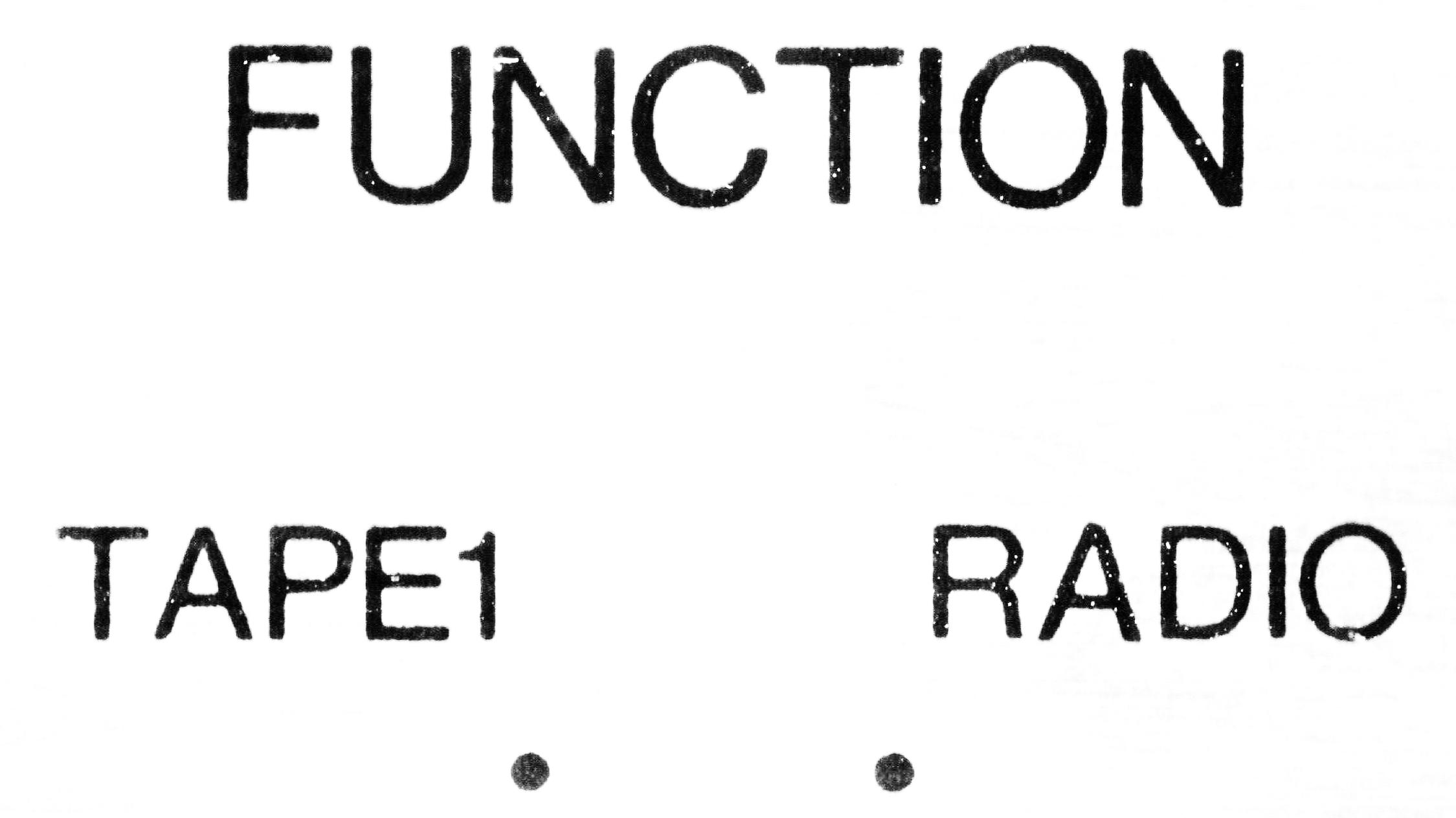

After doing some very minor rotations on the images to line them up perfectly, I needed to vectorize them for use in CAD. Not so much as a direct copy, but rather a guide to where to place the new text and graphics. First I tweaked on the contrast and brightness to make the text stand out from the gray background:

Then I loaded the image into Inkscape, a free tool that cutter plotter owners rant and rave about. It will trace bitmaps and text, which can then be saved as a DXF.

After I converted all the required characters, I merged them with the converted scans and mechanical drawing. I had to bring in the scan in three pieces, they all converted a bit differently so it looks a bit messy in some areas where they overlap. In many cases I improved on the original placement.

The spacing between the letters was all over the map, so I would line up a word vertically best I could and then drag the letters left and right until they matched.

After doing some very minor rotations on the images to line them up perfectly, I needed to vectorize them for use in CAD. Not so much as a direct copy, but rather a guide to where to place the new text and graphics. First I tweaked on the contrast and brightness to make the text stand out from the gray background:

Then I loaded the image into Inkscape, a free tool that cutter plotter owners rant and rave about. It will trace bitmaps and text, which can then be saved as a DXF.

After I converted all the required characters, I merged them with the converted scans and mechanical drawing. I had to bring in the scan in three pieces, they all converted a bit differently so it looks a bit messy in some areas where they overlap. In many cases I improved on the original placement.

The spacing between the letters was all over the map, so I would line up a word vertically best I could and then drag the letters left and right until they matched.

jimmyjimmy19702010

Member (SA)

The quality of the new metal is just so far superior to the original! You really need to replace all panels to get it all to match.

Well done on your extensive work so far. Pity I don't have a C100 to upgrade.

Well done on your extensive work so far. Pity I don't have a C100 to upgrade.

CSI

Member (SA)

Just joined this forum and am very impressed to see the work you've done Caution. I've got a Conion CF100 with the broken tape door. i've got the mechanism but it missing its spring, perspex and the trim panel with the graphics. Would be great to replace, trouble is mine is unusal in that it's in a brushed brass / gold colour. Is there a chance you might be able to get one done to match (can always supply you with a sample of the colour) ?

Thanks CSI I appreciate the feedback. Any laser shop worth their salt should be able to cut whatever you want. Whether or not they stock brushed brass is the question. You might have to supply the material if they can't get it. Not sure yet if this 26 gauge stainless I used can even be bent 1mm from the edge, might have to start over with 28 gauge aluminum. It was not available from the shop I used but I'm sure it could be found.

Do you know if the other trims you have are really brass? I'm thinking it's aluminum like the other units, but has been "iridited" with a yellow chromate. We used to do this to aluminum when I worked in a shop.

Do you know if the other trims you have are really brass? I'm thinking it's aluminum like the other units, but has been "iridited" with a yellow chromate. We used to do this to aluminum when I worked in a shop.

CSI

Member (SA)

Yes it's the gold one. How can i post an image of it here ?

I found the exact match from a stick on sign from the hardware shop (for toilets or something - the screenprint came off easily with some thinners) but the it's a little too thick. i'll make an effort to see if i can find the correct material in the right shade of 'brass'

Also looking for the spring (can't imagine that's going to be easy though) and also replace the perspex - does anyone have the spec for this they can help me with ?

Thanks All

I found the exact match from a stick on sign from the hardware shop (for toilets or something - the screenprint came off easily with some thinners) but the it's a little too thick. i'll make an effort to see if i can find the correct material in the right shade of 'brass'

Also looking for the spring (can't imagine that's going to be easy though) and also replace the perspex - does anyone have the spec for this they can help me with ?

Thanks All

stragulus

Member (SA)

The spring is not that hard. Find a wire that has about the right tension and thickness, and you can easily roll it into the correct shape with needle nose pliers. Standard paper clips are a decent match, although they are generally just a little too short. I have done this before, but I had another one to copy from. Remind me and I'll post a picture of it later.

(edit) My Helix has a spring that is rolled on 2 sides. Those sides slide over a pin on each side the tape door itself. Then there are 2 protruding ends that go into 2 holes the boombox case. My clairtone only has one hole in the case for some reason, but that was the box that was missing the spring. For the clairtone it probably only needs a spring rolled up on one side then, in which case a normal paperclip would be long enough.

(edit) My Helix has a spring that is rolled on 2 sides. Those sides slide over a pin on each side the tape door itself. Then there are 2 protruding ends that go into 2 holes the boombox case. My clairtone only has one hole in the case for some reason, but that was the box that was missing the spring. For the clairtone it probably only needs a spring rolled up on one side then, in which case a normal paperclip would be long enough.

Thanks. That's strange... both of my cases are missing a hole for the right side of the spring (as oriented in the pic) to stick through. I was always looking at the side without a hole, there's just a little dimple, so I thought the spring had to be reaally short to sit in that rather than stick through. I made a spring for the side with a hole and although It opens a tad slow it works now.

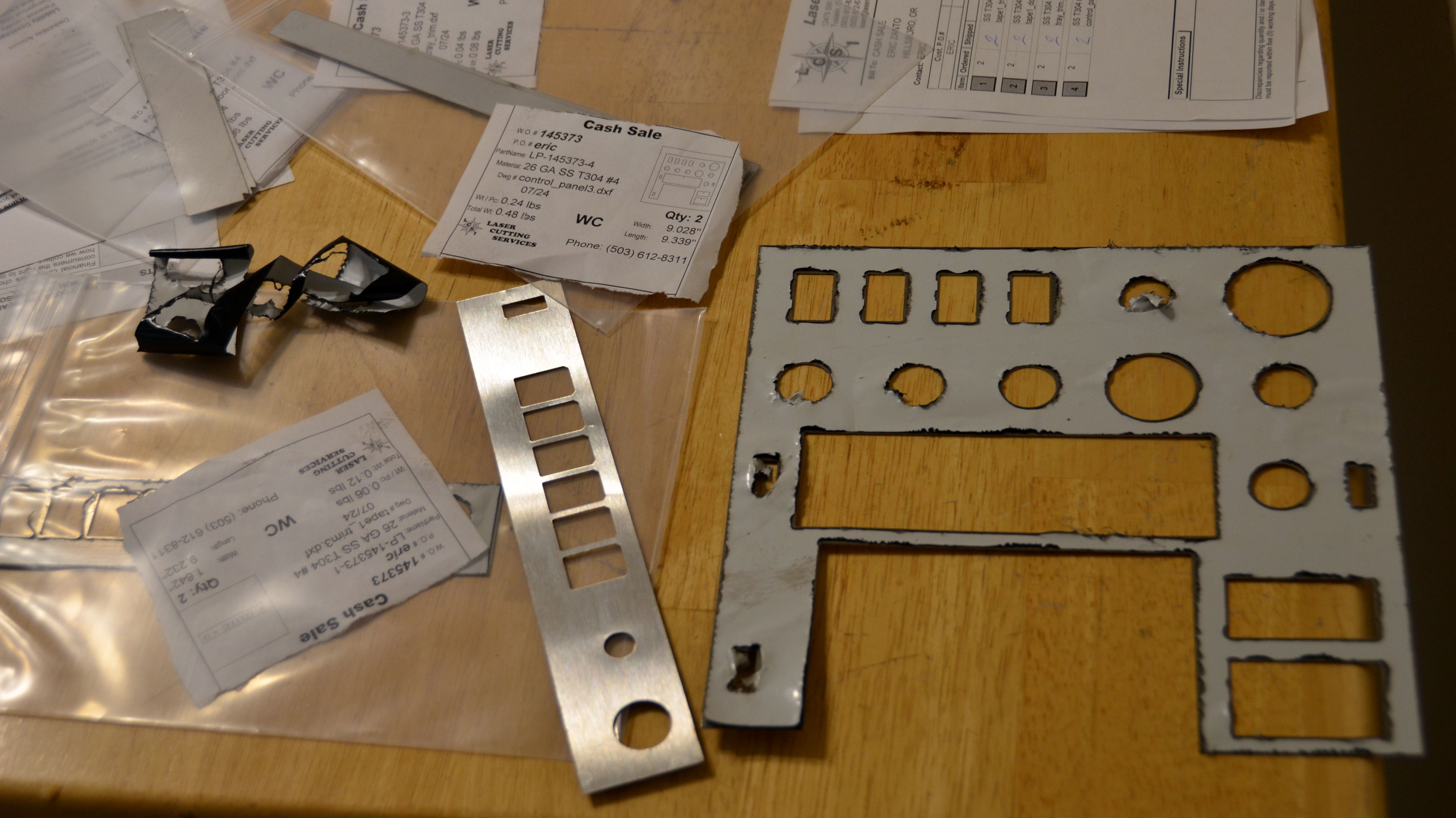

The panels should be ready tomorrow, and the bending brake arrives, but still need to find some of the same material to practice on first.

The panels should be ready tomorrow, and the bending brake arrives, but still need to find some of the same material to practice on first.

CSI

Member (SA)

Mine too only has a hole on the right hand side (view straight on) and a dimple for an un-drilled hole on the left had side. i was just going to drill this through and use the 2 ended spring that Stragulus is showing, unless someone has got a reference of an original one sided spring ?