I thought for sure the yellowing was stained permanently, but I started w/ 320 grit/400/500/600 then used Mothers aluminum wheel polish and that is the end result.. Surprised me too! Might hit it with 3M buffing compound and swirl mark remover to see if I can get it even glossier..hemiguy2006 said:Holy Carp, that tuner lens came out AWESOME!!!!!!!

CUSTOM COLORED CONION

- Thread starter JustCruisin

- Start date

- Status

- Not open for further replies.

It's a pity you can't get the front face plate remade from clear polycarbonate and get the labels reprinted on.

Seems a shame that the mid section of the colour gradient is going to be covered by a silver plate.

Scotty

Seems a shame that the mid section of the colour gradient is going to be covered by a silver plate.

Scotty

I thought the same thing, I'm gonna lose a lot of the blue once the faceplate goes on..Scotty_M said:It's a pity you can't get the front face plate remade from clear polycarbonate and get the labels reprinted on.

Seems a shame that the mid section of the colour gradient is going to be covered by a silver plate.

Scotty

Glucifer had the face plate reprinted for the custom M90. Ask how he did it.Scotty_M said:It's a pity you can't get the front face plate remade from clear polycarbonate and get the labels reprinted on.

Seems a shame that the mid section of the colour gradient is going to be covered by a silver plate.

Scotty

BTW, tuner lens...

I did all mine up in Publisher, using photos I then manually did every line and character over the top, then had it printed as a vinyl sticker. It took a lot of time and test fits to get right, but in this case I think it would be well worth the effort.

I've done the same thing with my GF-777 too.

My other suggestion would be to spray some clear colours over the panel, continuing the colours from the outside in.

It'd be tricky, but would finish the look really nicely I think. Either that or a clear gold/yellow.

You could cover the fascias in clear self adhesive book-covering type plastic and experiment a bit too.

Rock On.

I've done the same thing with my GF-777 too.

My other suggestion would be to spray some clear colours over the panel, continuing the colours from the outside in.

It'd be tricky, but would finish the look really nicely I think. Either that or a clear gold/yellow.

You could cover the fascias in clear self adhesive book-covering type plastic and experiment a bit too.

Rock On.

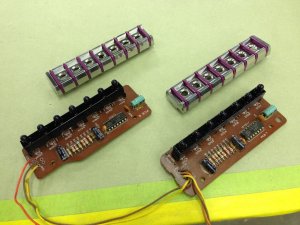

When I pushed my 777Z to its limits with 2.3 OHM BOSE woofers, there was much debate as to if the HAF-1392's would handle the draw & Norm mentioned that the C-100 uses a push-pull setup which roughly equates to a halving of loads vs. a normal single amp stage. So the 5.4 OHM speakers equate to roughly 2.7 OHMS load to each channel of the HAF IC's since they are in a push-pull setup. So your 4 OHM lasonics will result in each of the 4 channels running at a 2 OHM load. This is the very razor's edge of operating range for that CHIP due to the push-pull design. If you look at the entire data-sheet for the HAF-1392, it shows 2 OHM operation in its output graph's lower limit so it's a guess as to what the CONION will do under those conditions & relies heavily on the CAPS of the power circuit & amp circuit so keep an eye on it & don't leave it unattended for a while until you are sure it can handle the extra demand on the power. If you do decide to do this, at least clean the heat surfaces of the IC's & sink & reapply a thin coating of premium thermal compound before firing it up. It may save your investment....oldskool69 said:Frank is absolutely correct on the demand related to the amp chips (the point is avoiding clipping), but they are designed to go 4Ω ...See below.

Hitachi HA1392 Data Sheet Excerpt:

Conion C100 HA1392.jpg

HA1392 Amp Layout.jpg

The real question is the heat sink and components around it which allow it to breathe. See the heat sink on the photo below of the Conion/Helix and whatever other name it has.

dsc06989bvn.jpg

Look at the white stuff around the chip. Do you think it has solid contact with the heat sink and sufficiently, properly applied thermal paste across the entire chip? My two cents and common sense says no. This is where removal of the heat sink, cleaning of chip and heat sink, verification and adjustment of fit up is done, then application of fresh thermal transfer paste, and reassembly is done. I can tell you straight up that when I have a need to open mine up it's something I do as long as I'm in there. The paste WILL break down over time and heat cycles create gaps and air pockets. Or, depending on the makeup, become an oily residue similar to what happens when peanut butter loses it bond and you see the oil on top.

On another note, although it's not a gigantic heat sink, it is finned which is what you want versus some small plate of aluminum or steel seen in a great many boomers. Also check for loose connections and leaky caps. (If you look just above the phono/aux switch you'll see what I mean about the caps.)

BTW, my 777Z has all four BOSE woofers @ 2.3 OHMS nominal & still bumpin' strong so bring on your rainbow CONION for a sound off, if you dare to......mine is pumping out about 50 Watts RMS usable output...

https://www.youtube.com/watch?v=XPf9nUOyO-E&list=UU8dvRdzmRSNoWOyxr2GYHeA

Cheers,

Cpl

Sorry, missed that post but wanted to warn you about 4 ohm woofers....looking ill so far....JustCruisin said:Cool story bro.. Not sure if you read, but I'm keeping the speakers stock..

Man.....I'm still waiting to see this 1 done. I'm sorry, but for me this is the best looking paint job yet. I can picture it gleaming in the summer sun with a slick gloss overcoat & mirror chrome....bumpin' some beats...

Cpl

Cpl

- Status

- Not open for further replies.