The catch of course being there's another problem waiting on my sharp vz3500.

Finally I got the record player to spin (yay) but it's spinning too fast kind of pinky and perky fast .

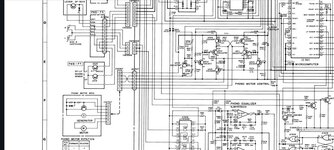

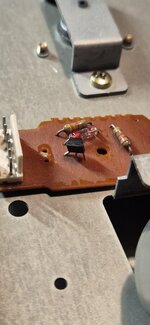

The variable resistors on the board do absolutely nothing and neither does the 45/33 button and there's no speed adjustment on the motor. All I can think of is the belt maybe wrong but I've tried two different ones .

If anyone has any ideas I'd be eternally grateful.

Pete

Finally I got the record player to spin (yay) but it's spinning too fast kind of pinky and perky fast .

The variable resistors on the board do absolutely nothing and neither does the 45/33 button and there's no speed adjustment on the motor. All I can think of is the belt maybe wrong but I've tried two different ones .

If anyone has any ideas I'd be eternally grateful.

Pete

)

)