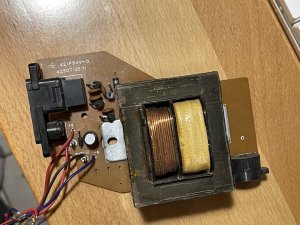

5 years ago, another member asked me to fix his M-X720. Problem was disovered to be a toasted power/function switch and later on, issues on the main PCB (probably the dolby chip). Anyway, as luck would have it I guess, rather than have me rebuild his main switch, he found a beater box and had it shipped to me. From this, I was able to restore his boombox. The beater was in bad shape but it would not power up. Turns out the power supply was shattered. Initially it didn't look too bad. Until you flipped it upside down, then you can see the evidence of repairs that were attempted. Even from the component side, if you look closely, you can see the cracks. Boards like this can't really be "fixed" because of the design. Basically, the transformer is screwed onto 2 screw towers, but sideways. It's a very heavy transformer. The transformer is also soldered onto the PS board, which is further anchored onto a 3rd screw tower. Basically the transformer relies on the PCB to keep it from pivoting down making the PCB a structural part of the transformer mounting system. Poor design in my opinion. A big shock and the twist will shatter the PCB which is exactly what happed here. There is external evidence of damage to the case, so the drop/shock was signficant.

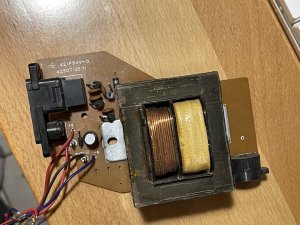

Here is the PCB from the top. Doesn't look too bad, but if you look very carefully, you'll see signs....

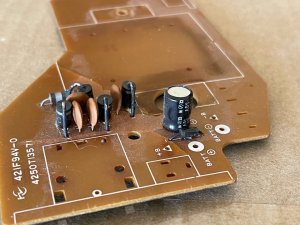

Transformer removed, Oh oh, can see some cracks more clearly now.

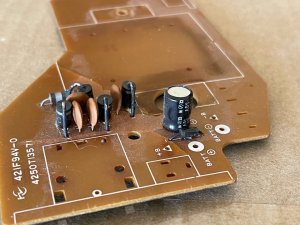

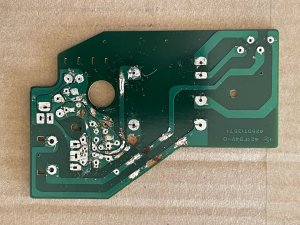

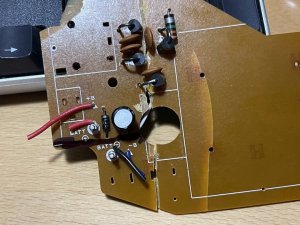

Ok, now we can see the attempted repairs. Didn't work apparently. No wonder, with it looking like humpty dumpty, theres no way any trace breaks will retain integrity because that transformer weighs over 2 pounds, almost a KG. When that flexes, trace repairs just breaks again.

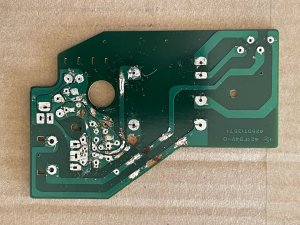

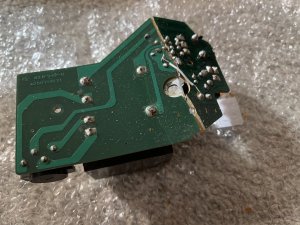

Board cleaned up. But this isn't going to be reused. No way any fix is going to be reliable.

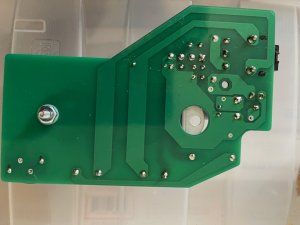

Here is the PCB from the top. Doesn't look too bad, but if you look very carefully, you'll see signs....

Transformer removed, Oh oh, can see some cracks more clearly now.

Ok, now we can see the attempted repairs. Didn't work apparently. No wonder, with it looking like humpty dumpty, theres no way any trace breaks will retain integrity because that transformer weighs over 2 pounds, almost a KG. When that flexes, trace repairs just breaks again.

Board cleaned up. But this isn't going to be reused. No way any fix is going to be reliable.

for taking time away from his busy life and agreeing to assist with this. The new board is FR4 which is fiberglass reinforced and much stronger than the old board. Also, any unused straggler holes on the original board was omitted to improve structural strength and avoid weak spots where cracks could form. Once the design was complete, I ordered the board to be cut by a PCB manufacturer. In the old days, I would use blank boards and etching solution to make and although I still have a quart of the solution, it's probably no good anymore and I'm too old to deal with that, especially with better options. You just need to pay some and have lots of patience. New board arrived and it's a beauty.

for taking time away from his busy life and agreeing to assist with this. The new board is FR4 which is fiberglass reinforced and much stronger than the old board. Also, any unused straggler holes on the original board was omitted to improve structural strength and avoid weak spots where cracks could form. Once the design was complete, I ordered the board to be cut by a PCB manufacturer. In the old days, I would use blank boards and etching solution to make and although I still have a quart of the solution, it's probably no good anymore and I'm too old to deal with that, especially with better options. You just need to pay some and have lots of patience. New board arrived and it's a beauty.