Try turning the entire thing upside down so you can rest the deck on the table.

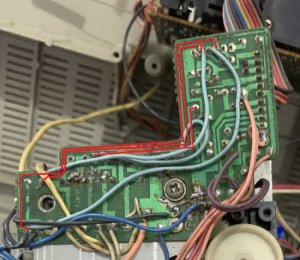

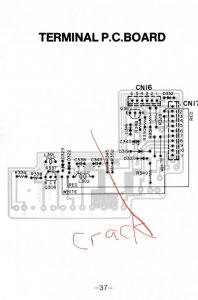

It is hard to tell from the photos the number of connections across that break.

I would just focus on making sure that you have checked the sections where the previous fix tried to just use solder to jump the connections.

Then by eye, check that you can see all tracts that should be connected cross the break and use your multimeter to test you have continuity.

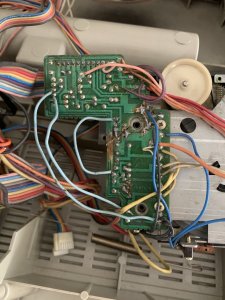

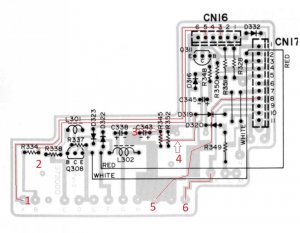

You could probably just strip some wires from a cord or try use something similar to what is already there.

Here are a few was an example.

View attachment 49426

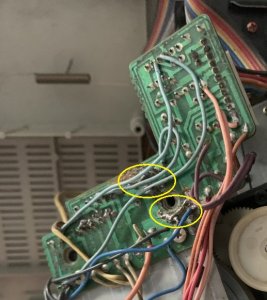

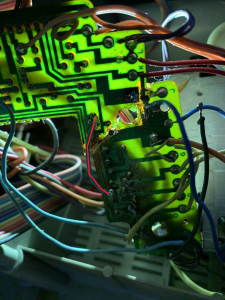

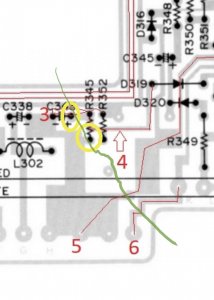

Again it is hard to tell but there is something going on around here:

View attachment 49428

If it is just blobs of solder to connect or bridge over the break in the board, I would remove it all by heating with soldering iron and using solder sucker and ensure you have a solder point on either side, then do the glue work making sure the board is together and attach the wire to connect across afterwards.