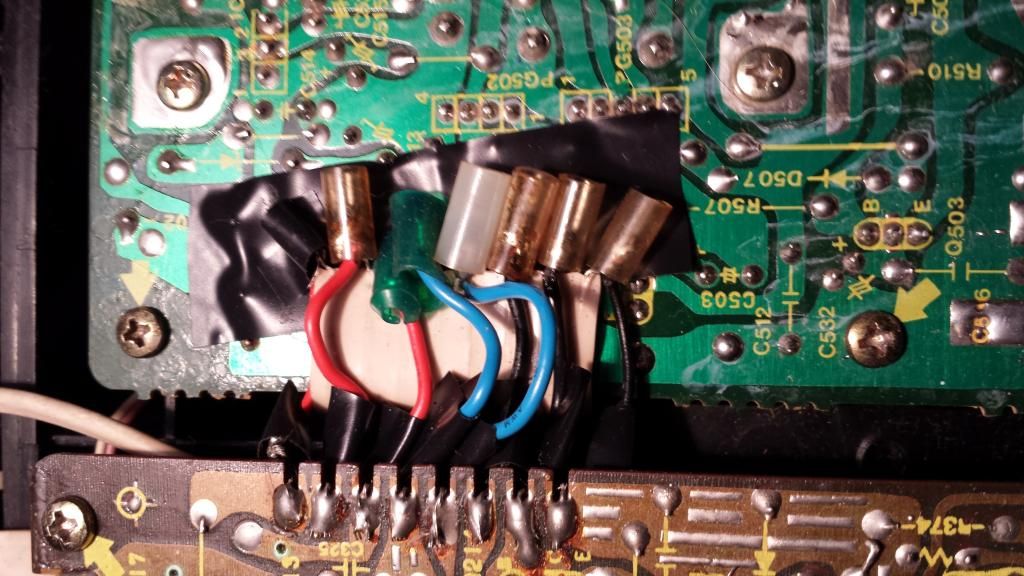

Hi everyone, I have had a 9595 for quite sometime but it had a bad transformer and the voltage wheel was disconnected anx it was workinv but weak, well after getting a little help I got proper output voltage but upo. Testinv the power supply I accidentally touched a wire and she went completely dead.

Well after asking for help here I receieved a complete power supply board and transformer and voltage wheel all complete thanks to Devol-Toni!!!☺

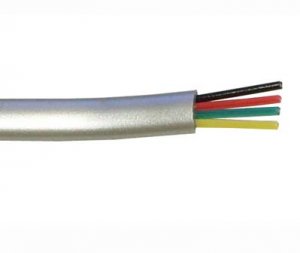

I have a question the 8 wire ribbon that connects to the main board, what is the best way to connect this?

I feel that if I gently pull the plastic covering off of the 8 wires coming off the main board and leave about 3/4" of wire then solder the 8 wires coming out of the power supply board that would be the best appriach6.

I do want to keep as much insulating factor on this connectio as it has a plastic coating ribbon feature on this connection.

Any advice would be welcome.

I really enjoy restoring and working on Sharp GF's! I have restored at least 3 so far.

thanks guys!📼📼📻🎵🎼🎶📼📻

-

-

-

Well after asking for help here I receieved a complete power supply board and transformer and voltage wheel all complete thanks to Devol-Toni!!!☺

I have a question the 8 wire ribbon that connects to the main board, what is the best way to connect this?

I feel that if I gently pull the plastic covering off of the 8 wires coming off the main board and leave about 3/4" of wire then solder the 8 wires coming out of the power supply board that would be the best appriach6.

I do want to keep as much insulating factor on this connectio as it has a plastic coating ribbon feature on this connection.

Any advice would be welcome.

I really enjoy restoring and working on Sharp GF's! I have restored at least 3 so far.

thanks guys!📼📼📻🎵🎼🎶📼📻

-

-

-