m40dotcom

Member (SA)

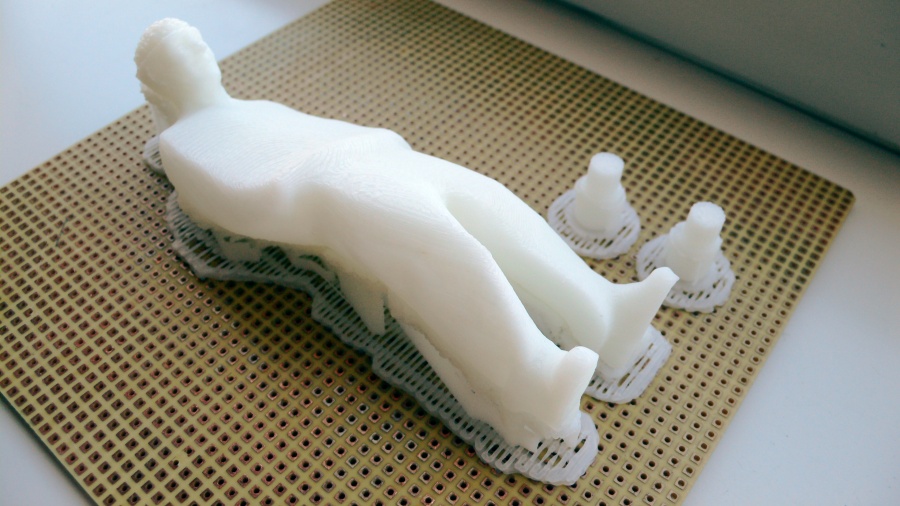

I'm not gonna be the last person to say it, but DAMN that is sick. Not sure you wanted to share that ability with all us as you're going to get a few hundred requests for various knob, switches and the like.

Now who on the board is a CAD head? We gotta have somebody? Last time I did 3D modeling it was in 3D Studio that ran in DOS. My uncle uses CAD for designed new Target floor plans, so you'd think a knob or two wouldn't be tough. I could ask around with him and others he works with about it.

Between someone with basic CAD skills and some time on their hands, and your 3D printer, I think you'll have a heck of a business of orders from everyone on the board. I'd bet that if all the members knew of this, you could get a list of 'orders' and probably crank out a couple dozen Lasonic knobs, some M70/M90 and Conion C100F knobs and the like. Instead of doing a ton of one offs, get all the orders from everyone and then do a run of them all at once. You just get to figure out a price that's worth your time, same for the CAD work person. I know I'd pay $7+ to get a missing switch, knob, or otherwise.

Now if you could get a printer that could do battery cover sized items, there's another 200 orders.

Just my thoughts. Damn I wish I had one of those things. I'd be printing missing parts for Boxes, old Transformer toy missing pieces, etc etc etc.

Now who on the board is a CAD head? We gotta have somebody? Last time I did 3D modeling it was in 3D Studio that ran in DOS. My uncle uses CAD for designed new Target floor plans, so you'd think a knob or two wouldn't be tough. I could ask around with him and others he works with about it.

Between someone with basic CAD skills and some time on their hands, and your 3D printer, I think you'll have a heck of a business of orders from everyone on the board. I'd bet that if all the members knew of this, you could get a list of 'orders' and probably crank out a couple dozen Lasonic knobs, some M70/M90 and Conion C100F knobs and the like. Instead of doing a ton of one offs, get all the orders from everyone and then do a run of them all at once. You just get to figure out a price that's worth your time, same for the CAD work person. I know I'd pay $7+ to get a missing switch, knob, or otherwise.

Now if you could get a printer that could do battery cover sized items, there's another 200 orders.

Just my thoughts. Damn I wish I had one of those things. I'd be printing missing parts for Boxes, old Transformer toy missing pieces, etc etc etc.