Day-um, those D-stem Mk III 931 volume/balance knobs are scarce, and I need two.

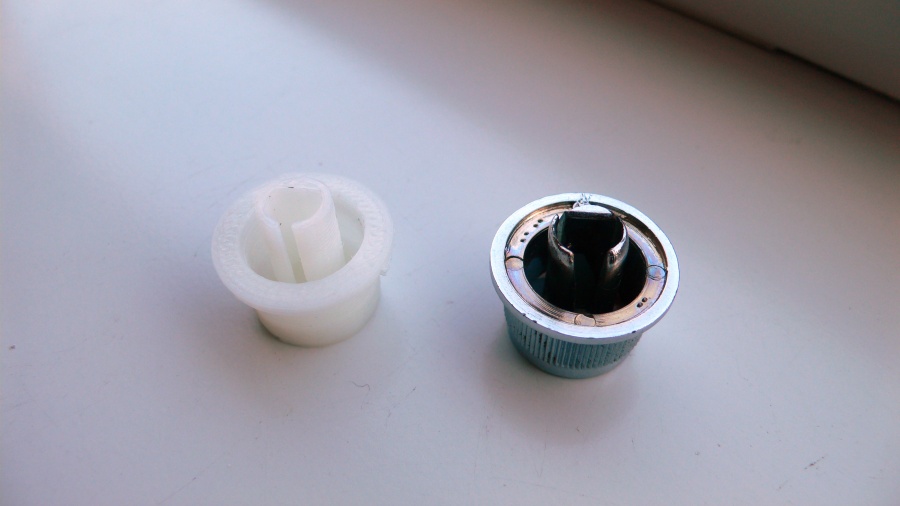

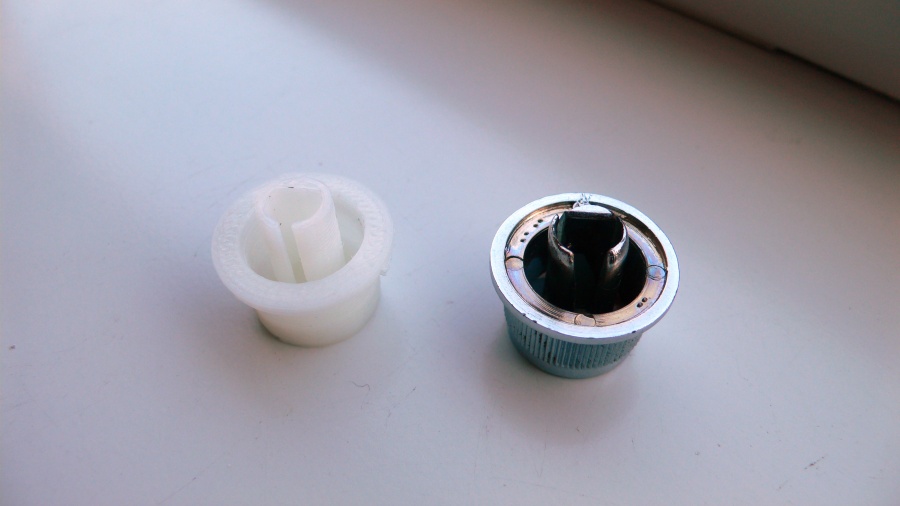

Not being easily deterred, I decided to print one on my 3D Printer.

Here's my first stab at it, and although a little rough, the knob fits and functions perfectly.

I'll re-print it at a finer resolution, sand and finish with chrome paint. Hopefully it'll match well enough.

I'll keep you guys posted on the progress...

Go!

=m i l e s=

Not being easily deterred, I decided to print one on my 3D Printer.

Here's my first stab at it, and although a little rough, the knob fits and functions perfectly.

I'll re-print it at a finer resolution, sand and finish with chrome paint. Hopefully it'll match well enough.

I'll keep you guys posted on the progress...

Go!

=m i l e s=

Keep us informed as they look real good

Keep us informed as they look real good