Preserving chrome trim?

- Thread starter Reli

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

I just had to paint the chrome pieces on my Crown 5100 because of horrible pitting :'-( . I didn't want to do it but it looked like crap no matter how much I cleaned or waxed the pieces. Satin black grills and red grills will be kick ass on this box anyway  . :sin:

. :sin:

. :sin:

. :sin:After cleaning them, sealing them with a clearcoat is my recommendation. I know for a fact that WD-40 exposure for more than a few hours could cause the coating to simply wipe off. So if the wax includes a petroleum base, I personally would avoid it since plastic chrome is not a true chrome. Just google and you'll find that it's usually a decorative and not a durable coating. There are some chrome that is actually metal like on handle brackets. But most of the ones on tweeter and woofer bezels, etc, are just the decorative variety.

Hmm, I knew there was a complex process involved in chrome-plating metal parts such as old car bumpers.......But for plastic trim, I always thought it was just a spray coatingJVC Floyd said:as far as i know chrome plating consists of 3 steps

dipping in copper

then dipping in nickel

finally dipping in chrome

all these metals are deposited on the part with the use of electrical current and other methods i don't know much about

Thanks Norm. Do you have a recommendation on brand of clearcoat?Superduper said:After cleaning them, sealing them with a clearcoat is my recommendation. I know for a fact that WD-40 exposure for more than a few hours could cause the coating to simply wipe off. So if the wax includes a petroleum base, I personally would avoid it since plastic chrome is not a true chrome. Just google and you'll find that it's usually a decorative and not a durable coating. There are some chrome that is actually metal like on handle brackets. But most of the ones on tweeter and woofer bezels, etc, are just the decorative variety.

There HAVE been a lot of parts I've considered clearcoating (both plastic and metal parts), but I"ve always been leery of it because the clearcoat the manufacturers used seems to turn yellow over time, or develop weird spots underneath.

The chrome on plastic is almost always vacuum metallized aluminum.

Taken from http://www.muellercorp.com/chromeplatingplastic.htm

Many People think it is impossible to chrome plastic, it is not. While it is possible to electroplate/chrome plate on plastic it is a difficult and expensive process. Vacuum metalizing is the most common process used for a chrome look on plastic. Vacuum metallizing is process used to make, toys, flash light reflectors and automotive trim, shine like chrome.

Vacuum metalizing DOES NOT have the same durability or corrosive resistance that chrome plating does.

Before parts are metalized they are washed and basecoated to ensure a smooth finish to coat over.

During the vacuum metallizing process aluminum is evaporated in a vacuum chamber, which than condenses back on and bonds to the parts to form a uniform layer, which shines like chrome.

After the metalizing takes place there is a protective topcoat applied similar to the ones used in the automotive industry. You can also add dyes to the topcoat to achieve bright chrome colors gold’s, bronze’s, copper’s, and gunmetal’s.

Chrome vacuum metalizing should not be cleaned with abrasive materials; you should only clean it with a damp soft rag. The chemicals in household cleaners can affect the clear coat causing it to become hazy or milky.

Vacuum metallizing conforms to the base material that is being coated. If there is texture, scratches, blister, etc it will show through the coating.

It is much more environmentally friendly and cost effective than chrome plating or chrome painting.

You can vacuum metalize many materials including plastic, metal, glass, fiberglass, and more. There are many different applications for Vacuum metallizing including; automotive and motor sport accessories, automotive interior trim, sporting goods, toys, models, novelty items, display items, decorative fixtures, cosmetic closures, etc.

Taken from http://www.muellercorp.com/chromeplatingplastic.htm

Many People think it is impossible to chrome plastic, it is not. While it is possible to electroplate/chrome plate on plastic it is a difficult and expensive process. Vacuum metalizing is the most common process used for a chrome look on plastic. Vacuum metallizing is process used to make, toys, flash light reflectors and automotive trim, shine like chrome.

Vacuum metalizing DOES NOT have the same durability or corrosive resistance that chrome plating does.

Before parts are metalized they are washed and basecoated to ensure a smooth finish to coat over.

During the vacuum metallizing process aluminum is evaporated in a vacuum chamber, which than condenses back on and bonds to the parts to form a uniform layer, which shines like chrome.

After the metalizing takes place there is a protective topcoat applied similar to the ones used in the automotive industry. You can also add dyes to the topcoat to achieve bright chrome colors gold’s, bronze’s, copper’s, and gunmetal’s.

Chrome vacuum metalizing should not be cleaned with abrasive materials; you should only clean it with a damp soft rag. The chemicals in household cleaners can affect the clear coat causing it to become hazy or milky.

Vacuum metallizing conforms to the base material that is being coated. If there is texture, scratches, blister, etc it will show through the coating.

It is much more environmentally friendly and cost effective than chrome plating or chrome painting.

You can vacuum metalize many materials including plastic, metal, glass, fiberglass, and more. There are many different applications for Vacuum metallizing including; automotive and motor sport accessories, automotive interior trim, sporting goods, toys, models, novelty items, display items, decorative fixtures, cosmetic closures, etc.

BoomboxLover48

Boomus Fidelis

Fatdog said:The chrome on plastic is almost always vacuum metallized aluminum.

Taken from http://www.muellercorp.com/chromeplatingplastic.htm

Many People think it is impossible to chrome plastic, it is not. While it is possible to electroplate/chrome plate on plastic it is a difficult and expensive process. Vacuum metalizing is the most common process used for a chrome look on plastic. Vacuum metallizing is process used to make, toys, flash light reflectors and automotive trim, shine like chrome.

Vacuum metalizing DOES NOT have the same durability or corrosive resistance that chrome plating does.

Before parts are metalized they are washed and basecoated to ensure a smooth finish to coat over.

During the vacuum metallizing process aluminum is evaporated in a vacuum chamber, which than condenses back on and bonds to the parts to form a uniform layer, which shines like chrome.

After the metalizing takes place there is a protective topcoat applied similar to the ones used in the automotive industry. You can also add dyes to the topcoat to achieve bright chrome colors gold’s, bronze’s, copper’s, and gunmetal’s.

Chrome vacuum metalizing should not be cleaned with abrasive materials; you should only clean it with a damp soft rag. The chemicals in household cleaners can affect the clear coat causing it to become hazy or milky.

Vacuum metallizing conforms to the base material that is being coated. If there is texture, scratches, blister, etc it will show through the coating.

It is much more environmentally friendly and cost effective than chrome plating or chrome painting.

You can vacuum metalize many materials including plastic, metal, glass, fiberglass, and more. There are many different applications for Vacuum metallizing including; automotive and motor sport accessories, automotive interior trim, sporting goods, toys, models, novelty items, display items, decorative fixtures, cosmetic closures, etc.

BoomboxLover48

Boomus Fidelis

Over the vacuum metallized plastic parts there must be a good coating to prevent it from weather resistance, scratch and abrasion resistance, mar resistance, and all. I believe they used some solvent based lacquer over it which helped it to some extent. This lacquer don't have good chemical resistance. In some cases weak solvents like mineral spirits can even wash it off. I would stay away from using any petroleum solvents. They should hold up well to butyl cellosolve or isopropyl alcohol. I've seen people using chrome polish over this only to wear off the little lacquer left on the surface and cause discoloration.

The vacuum metallized reflectors of cars use a weather resistant and very durable UV coating. Companies like Red Spot make these coatings for several auto OEM manufacturers. One can see the difference you see in with the old and new reflectors of cars. The new ones pretty much hold up to the UV degradation and weather.

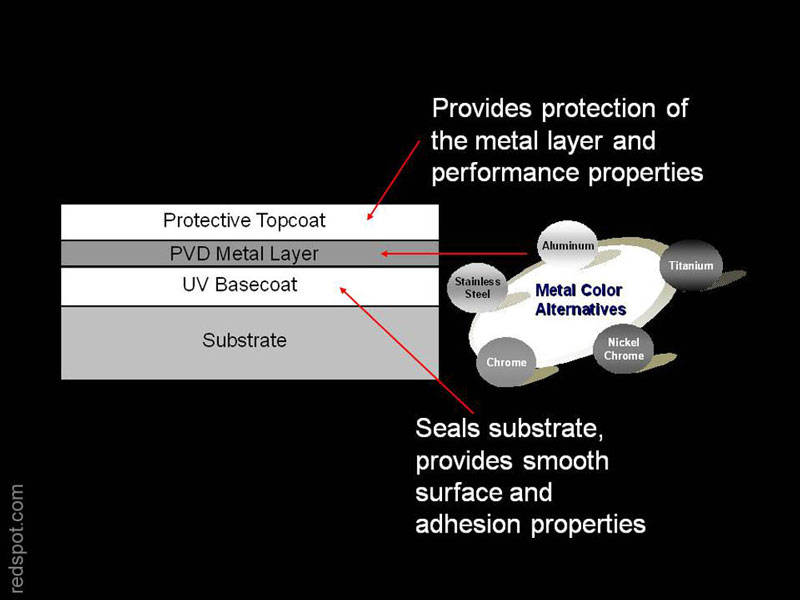

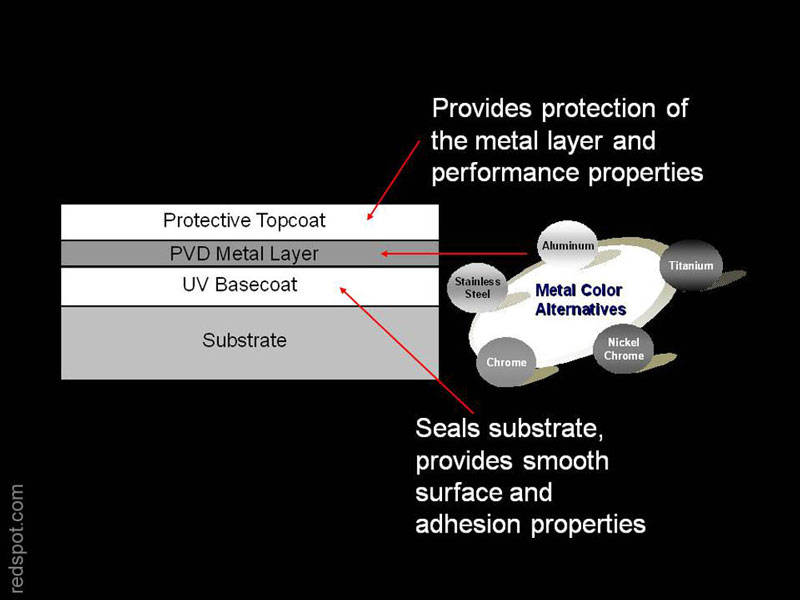

First a substrate is coated with a UV coating (primer/base coat- fortified adhesion promoters) and over it the vapor of a metal is deposited. Over the vapor deposited metal there is another layer of protective coatiing. The metal can me chrome, titanium, nickel, Al or stainless steel. This type of coating is called PVD.

Physical Vapor Deposition, or PVD, is a group of vacuum coating techniques that are used to deposit thin film coatings that enhance the properties and performance of tools and machine components. PVD coatings deposited using vacuum coating machines are used in a vast array of industries and hundreds if not thousands of applications as diverse as "self-cleaning" windows, medical implants, cutting tools, decorative fittings and Automotive components.

The vacuum metallized reflectors of cars use a weather resistant and very durable UV coating. Companies like Red Spot make these coatings for several auto OEM manufacturers. One can see the difference you see in with the old and new reflectors of cars. The new ones pretty much hold up to the UV degradation and weather.

First a substrate is coated with a UV coating (primer/base coat- fortified adhesion promoters) and over it the vapor of a metal is deposited. Over the vapor deposited metal there is another layer of protective coatiing. The metal can me chrome, titanium, nickel, Al or stainless steel. This type of coating is called PVD.

Physical Vapor Deposition, or PVD, is a group of vacuum coating techniques that are used to deposit thin film coatings that enhance the properties and performance of tools and machine components. PVD coatings deposited using vacuum coating machines are used in a vast array of industries and hundreds if not thousands of applications as diverse as "self-cleaning" windows, medical implants, cutting tools, decorative fittings and Automotive components.

redbenjoe

I Am Legend

Reli said:

Second question:

Is there any kind of treatment, like wax or vaseline, that could prevent those parts from getting pitted/corroded?

-----------------------------------------------

what kind // brand // model # of wax ( IF ANY) do you guys suggest to stop pitting ??

i use ' renaissance ' furniture polish --but dont fully trust it ?

BoomboxLover48

Boomus Fidelis

Once corrosion starts we can only slow it down and never stop it completely.  That is the simple answer.

That is the simple answer.

For pitting, a good wax or coating which can give some barrier properties will really help here.

That is the simple answer.

That is the simple answer.

For pitting, a good wax or coating which can give some barrier properties will really help here.

BoomboxLover48

Boomus Fidelis

Actually wax is not a film former. I would use something like new finish 2000 which is a polymer compound that lays a micro film. I believe Meguiar's Ultimate Quick Detailer is also a thin hydrophobic film former.

Radio 80's FM

Member (SA)

We have a company here in Perth that does spray chrome finishes:

http://www.fantachrome.com.au/

I'll leave it to you guys to judge the finished quality but I' d say it's better that most of us could hope to do ourselves.

Shane was gonna completely chrome a box but he seems to off the radar at the mo.

Shane! Ring me!!!

http://www.fantachrome.com.au/

I'll leave it to you guys to judge the finished quality but I' d say it's better that most of us could hope to do ourselves.

Shane was gonna completely chrome a box but he seems to off the radar at the mo.

Shane! Ring me!!!

BoomboxLover48

Boomus Fidelis

I just found one of the best Physical Vapor Deposition coatings with the state of the art technology on the top coat of 2006 Infiniti alloy wheel center ornament. Actually my son gave all four of those to me to clean it up, when he took the 19" OEM wheels out at the dealer for getting new tires.

Six years of all-weather abuse it took on Chicago roads and see how the wheel center ornament stood it all.

I wish we had the same type on our boomboxes.

Six years of all-weather abuse it took on Chicago roads and see how the wheel center ornament stood it all.

I wish we had the same type on our boomboxes.

Line Out

Member (SA)

Would be really interesting to see what kind of system is needed to plate plastics. I wonder how the aluminium is vaporized in the vacuum...? In Finland, I've heard that Oras, a manufacturer of faucets, had some times done platings to private customers. Though they haven't done it for a quite some time anymore. Their platings are really durable. 20 years of daily use of a faucet "handle" and just a few tiny scratches...

- Status

- Not open for further replies.