A solution to the infamous function switch broken gear that plagues the Lasonic TRC 920 and 931's Tape/Radio/Line In as well as the AM/FM selector switch has been found.

Over the last month I have been working with Trommelmops to solve this problem and with the help of DOCS it has been solved.

As you will see below, Trommelmops has managed to meticulously recreate the gear out of brass as a direct replacement.

SPECIAL THANKS TO DOCS for the assist! He mailed Trommelmops a spare switch for him to make the final measurements which helped him complete this job.

So, to start with. I mailed T.M. a broken gear that I had used in the past as a template to make gears by hand out of plastic. You can see two video's HERE and HERE which will help you replace the gear in the switch.

As you can see, the gear is not just a simple wheel with teeth. It's a complex design with bump stops and limiters. You can also see where the gear broke. It snaps in a weak spot between the teeth. There is such little material there, that it makes gluing it or repairing it virtually impossible.

Here you can see T.M. has taken bar stock and sliced long groves in it to make the teeth.

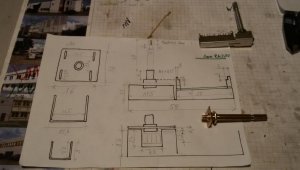

Next, you can see where T.M. made the holder, where the gearwheel and the cam are put on together in the right position.

He simply sliced the bar stock like a loaf of bread and he had gears!

Now, brazing on the tab

Next came fitting to the switch...

The gear is placed back on the knob shaft

And the knob shaft placed back into the switch case

The original gear was held in place by flattening the end of the shaft onto the gear. But there is a better way of doing this. So T.M. drilled and threaded a tiny hole in the side of the gear and used a M2x4mm screw to lock it in place. This does require a hex key size 0.9mm to tighten it. If you don't have one, T.M. can make you one for a small additional cost, just ask him when you order.

The last thing your going to want to do is put some sort of grease on the gear and track to keep it lubed.

And there you have it...

If your interested in a replacement gear for your function switch contact Trommelmops via direct PM.

The reality of the situation is this...

I have lost count on how many of these I have personally rebuilt. It's a job that you only want to have to do once, because it's a PITA to do. I have tried gluing the gears with super glue, epoxy, JB weld, hot glue guns and plastic weld. Nothing works. There just isn't enough materiel between the gear teeth to hold it together. So your left with only a few options. Replace the whole switch with a working switch from another Lasonic with another 35 year old plastic gear, make your own plastic gears as I show in the video's listed above or for a very reasonable price (ask Trommelmops for a quote) you can quite literally double the value of your 920 or 931 by fixing it's Achilles heel once and for all!

A HUGE thank you to Trommelmops for taking the time to engineer this gear, as you can see in the pictures, this is a massive undertaking.

Thank you again to DOCS for shipping Trommelmops a spare switch for him to use for measurements.

It's these group efforts that make it possible to keep these old radio's going.

Over the last month I have been working with Trommelmops to solve this problem and with the help of DOCS it has been solved.

As you will see below, Trommelmops has managed to meticulously recreate the gear out of brass as a direct replacement.

SPECIAL THANKS TO DOCS for the assist! He mailed Trommelmops a spare switch for him to make the final measurements which helped him complete this job.

So, to start with. I mailed T.M. a broken gear that I had used in the past as a template to make gears by hand out of plastic. You can see two video's HERE and HERE which will help you replace the gear in the switch.

As you can see, the gear is not just a simple wheel with teeth. It's a complex design with bump stops and limiters. You can also see where the gear broke. It snaps in a weak spot between the teeth. There is such little material there, that it makes gluing it or repairing it virtually impossible.

Here you can see T.M. has taken bar stock and sliced long groves in it to make the teeth.

Next, you can see where T.M. made the holder, where the gearwheel and the cam are put on together in the right position.

He simply sliced the bar stock like a loaf of bread and he had gears!

Now, brazing on the tab

Next came fitting to the switch...

The gear is placed back on the knob shaft

And the knob shaft placed back into the switch case

The original gear was held in place by flattening the end of the shaft onto the gear. But there is a better way of doing this. So T.M. drilled and threaded a tiny hole in the side of the gear and used a M2x4mm screw to lock it in place. This does require a hex key size 0.9mm to tighten it. If you don't have one, T.M. can make you one for a small additional cost, just ask him when you order.

The last thing your going to want to do is put some sort of grease on the gear and track to keep it lubed.

And there you have it...

If your interested in a replacement gear for your function switch contact Trommelmops via direct PM.

The reality of the situation is this...

I have lost count on how many of these I have personally rebuilt. It's a job that you only want to have to do once, because it's a PITA to do. I have tried gluing the gears with super glue, epoxy, JB weld, hot glue guns and plastic weld. Nothing works. There just isn't enough materiel between the gear teeth to hold it together. So your left with only a few options. Replace the whole switch with a working switch from another Lasonic with another 35 year old plastic gear, make your own plastic gears as I show in the video's listed above or for a very reasonable price (ask Trommelmops for a quote) you can quite literally double the value of your 920 or 931 by fixing it's Achilles heel once and for all!

A HUGE thank you to Trommelmops for taking the time to engineer this gear, as you can see in the pictures, this is a massive undertaking.

Thank you again to DOCS for shipping Trommelmops a spare switch for him to use for measurements.

It's these group efforts that make it possible to keep these old radio's going.

The screw is tiny and the hex key driver will broke then!!!!

The screw is tiny and the hex key driver will broke then!!!!  This is strong enough

This is strong enough