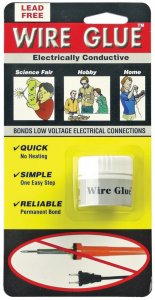

For those of us who have the PC-55 or PC-550 with the amazing lovely display in the cassette deck, we know the risks of that ribbon and the conductive glue it is attached with.

How did they do this in 1983? is that glue no longer available? Was it applied precisely in only the gaps?

Is there any way to fix this when elements stop lighting up and connection is lost?

Has anyone figured this problem out?

It's not a catastrophic problem, but it is one that happens, and I imagine will eventually cause many 55s displays to lose integrity. We need a fix. Any methods out there anyone has come up with?

I saw the soldering of wires - that's extreme, but an option. I'm thinking some type of fine and stiff metal wire clamp that's laminated should do the trick. The force needed here is not great. On the circuit board clamps should work, but what about the edges of the display? Doesn't seem like it would be complicated. Just needs to be bent to correct shape.

Other ideas suggestions? Anyone solve this? Was it on the board on at the display?

How did they do this in 1983? is that glue no longer available? Was it applied precisely in only the gaps?

Is there any way to fix this when elements stop lighting up and connection is lost?

Has anyone figured this problem out?

It's not a catastrophic problem, but it is one that happens, and I imagine will eventually cause many 55s displays to lose integrity. We need a fix. Any methods out there anyone has come up with?

I saw the soldering of wires - that's extreme, but an option. I'm thinking some type of fine and stiff metal wire clamp that's laminated should do the trick. The force needed here is not great. On the circuit board clamps should work, but what about the edges of the display? Doesn't seem like it would be complicated. Just needs to be bent to correct shape.

Other ideas suggestions? Anyone solve this? Was it on the board on at the display?