Im on a roll... Sharp GF 525

- Thread starter wowminister

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

wowminister said:Ha

You have some lovely vans in the USA already. You don't need mine.

No, no -- I want YOURS.

And we have nice emissions legal conversion kits to install subaru engines into those vans so they can keep up with the rest of the pintos and vegas out there.

And we have nice emissions legal conversion kits to install subaru engines into those vans so they can keep up with the rest of the pintos and vegas out there.Ok, I'll make it a GF-777 and TWO M70's.

mmcodomino

Member (SA)

Superduper said:wowminister said:Ha

You have some lovely vans in the USA already. You don't need mine.

No, no -- I want YOURS.And we have nice emissions legal conversion kits to install subaru engines into those vans so they can keep up with the rest of the pintos and vegas out there.

Ok, I'll make it a GF-777 and TWO M70's.

GF777, M70, Intersound Super Jumbo AND a VZ2000 for your bus!

Amazing one, a very nice example of a classic T2. My dad always wanted a T1 Samba

.

.Is your drivon from the right seat or from the left seat as a UK vehicle?

Its right hand drive,

Here it is inside, no cushions or curtains as they were being made at the time.

So as you can see, no amount of boomboxes is gonna make me trade ..

Its a nice thought though.

Here it is inside, no cushions or curtains as they were being made at the time.

So as you can see, no amount of boomboxes is gonna make me trade ..

Its a nice thought though.

Had a chance to open the box up.

First, the power switch... All in good order, but not sure how it connects to the power unit on the bottom left of the box.

Looks like a slide that vanishes into the mechanism where the transformer is. Looks like it is not connected in there ???? Should it be ????

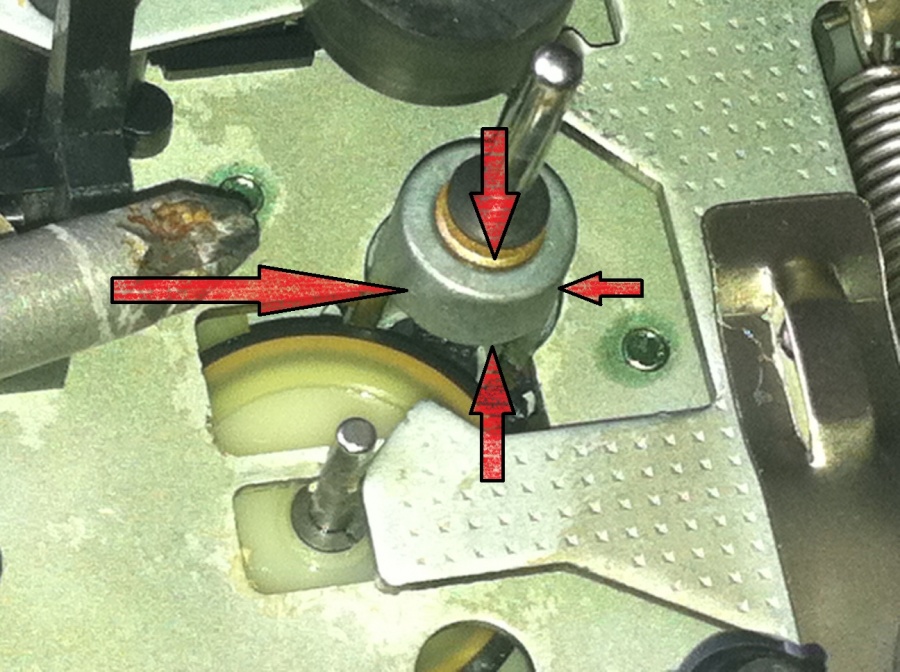

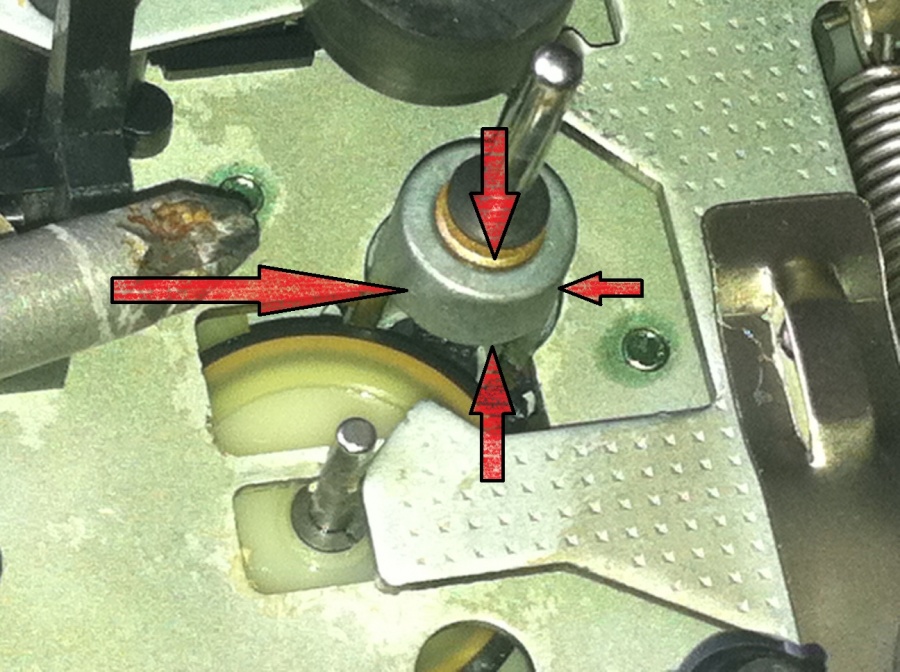

Next the duff tape drive.

Looks like the connection from the pinch to the drive has melted ????

First, the power switch... All in good order, but not sure how it connects to the power unit on the bottom left of the box.

Looks like a slide that vanishes into the mechanism where the transformer is. Looks like it is not connected in there ???? Should it be ????

Next the duff tape drive.

Looks like the connection from the pinch to the drive has melted ????

That happens to almost every Sharp boombox. The capstan tire turns to a black, gooey mess.wowminister said:Next the duff tape drive.

Looks like the connection from the pinch to the drive has melted ????

Here's a thread for help with that:

viewtopic.php?p=36682

Just to be super clear, we are talking about the same wheel ???

Does this come out without having to remove the whole mechanism, that would be handy.

Does this come out without having to remove the whole mechanism, that would be handy.

You need to undo the mechanism from the backside and pull the flywheel out. When you do that, the capstan needle will pull through. Watch for and catch the capstan needle washer that will likely fall off from the front side. Save it because you will replace that washer when you are done restoring that wheel. At this point, use lots of Q-tip swabs and isopropyl to remove all traces of the melted wheel. It could take a long time. Some guys like to use windex. I've never used windex but prefer not to use water based cleaners since it doesn't evaporate as quickly as the alcohol solvent. I also cut the tip off the swab and push the entire stick through since the goo is probably inside the bushing too. If you don't remove all traces of it -- it will contaminate and add drag to tne spinning needle. Once all that is done, you'll need to find an appropriately sized silicone tubing from a hobby store and snip a length to fit. Place it into that opening and push the capstan needle back through. Hopefully, it should thread through the tubing and be fat enough to drive the other wheel.

fatdog posted the dimensions someplace, but the size he recommended somehow did not work for me. There might be different sizes for each model. What I did was pay a personal visit to the R/C hobby store and purchased an assortment. Then tried each one until I found one that fit and worked. Unfortunately, I didn't note which size it was so I can't report on that.

Good Idea.

I will have to take the capstan out again (at the moment I cant leave a mess round the house as we are in the middle of selling it, so I'm under orders to stay tidy)

I will have to take the capstan out again (at the moment I cant leave a mess round the house as we are in the middle of selling it, so I'm under orders to stay tidy)

It was in the thread that was linked.wowminister said:Would you know the inner and outer diameter of that bit of silicone ???

Cheers

Tim

Outside diameter= ~0.215" to 0.22"

Inner diameter = ~0.0455" to 0.05"

Then use some sand paper to rough up the outside after trimming."

- Status

- Not open for further replies.