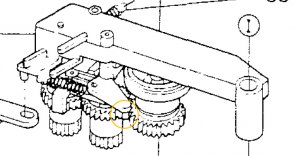

That same issue is happening to many electronics now. What happens is that the part is nylon and the hole is intended to be an interference fit. Over time, the nylon shrinks which causes it to split on the area of stress (interference fit). The split makes the hole lose it's grip. Eventually, the nylon might crumble. Probably the most famous example is on the Sony CRF-320/330 shortwave radios. 3 of the gears are like this but develops exactly this split, which causes the pressed pin to lose it's grip and spin. In short, the tuning knobs no longer moves the dials. These are expensive radios and collectors had been buying very expensive brass replacements, then overpriced china reproductions (over $100 a set of gears you would expect to cost about $0.50c to manufacture). The prices on those same parts (by competing vendors) now have dropped to the $30's I see.

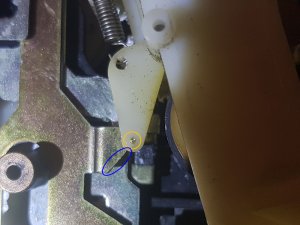

In this case, I'm not sure how critical that part is but if it's just a locator pin and won't fall out on it's own, might continue to function for years just placed back in there like that.