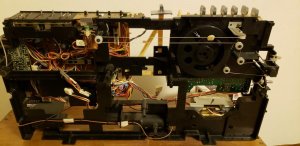

My newest addition (RC-M70) has been like a demanding beautiful woman ever since it showed up. I fell in love with it but soon after I got it, it started demanding attention time and time again at my expense. It's been give and take. I work on it. It plays for a few days then something comes up. Fix that issue. Plays another 2 days then something else. So far this box has been the most demanding box I've owned. I take it under my wing and clean her up and show some love. It plays well and then 2 days later throws a tantrum. I seriously don't think I've made it more than 2 days at a time without having to open it up for something or another. I keep hearing how bullet proof these are and I am waiting to get that result..lol. Its never the same thing. What I fix, stays fixed but then it's something else.

What prompted this post? Well get this.

I had just finished commenting to my wife this evening how this would be two days since my last repair. I commented that I bet it's about to do something stupid and crap out....and wouldn't you know, I'm playing a tape and a good song finished playing. So I use the music search to rewind and replay...which it did. But when the song started playing it sounded like they were playing at the bottom of the ocean using a waterproof mic to capture the audio. Fearing that it was shredding my tape I stopped and ejected.

So anyway, the stinking brass bushing popped out of the capstan housing and was causing the whole flywheel and capstan spindle to flop around like a dead Turkey in a clothes dryer. WTF? Seriously?

I pushed it back into the housing and the little plastic washer on the end seems to have clicked and locked it back in. It doesn't appear to be spinning in the housing so who knows. If it pops put again I'll apply a light glue on the outer diameter when I press it back in so it won't pop out anymore. It's not worn on the spindle end. But its stuff like this.

Also the leaf switch for the pause button broke before this causing the stop circuit to engage when paused making the mechanism go into a metal on metal clinking frenzy...repaired. Then the strap clip breaks....repaired, then before that the left volume slider wants to be all grabby....fixed, then the tape player started to play too slow after adjustments.....fixed again, then the stereo indicator didn't want to work...adjusted VR31....fixed, then the main power leaf switch didn't want to make connection when turned on.....fixed, then while playing a tape left channel drops..dirty function switch....fixed, then it would keep stopping while playing a tape...narrowed that down to a sticking tape counter that would trip the stop circuit solenoid.

It's all getting fixed but damn.....she's a demanding little b***h. But when it's working I'm on cloud nine

Anyone else with a box like this? Does it ever get better or worse?

What prompted this post? Well get this.

I had just finished commenting to my wife this evening how this would be two days since my last repair. I commented that I bet it's about to do something stupid and crap out....and wouldn't you know, I'm playing a tape and a good song finished playing. So I use the music search to rewind and replay...which it did. But when the song started playing it sounded like they were playing at the bottom of the ocean using a waterproof mic to capture the audio. Fearing that it was shredding my tape I stopped and ejected.

So anyway, the stinking brass bushing popped out of the capstan housing and was causing the whole flywheel and capstan spindle to flop around like a dead Turkey in a clothes dryer. WTF? Seriously?

I pushed it back into the housing and the little plastic washer on the end seems to have clicked and locked it back in. It doesn't appear to be spinning in the housing so who knows. If it pops put again I'll apply a light glue on the outer diameter when I press it back in so it won't pop out anymore. It's not worn on the spindle end. But its stuff like this.

Also the leaf switch for the pause button broke before this causing the stop circuit to engage when paused making the mechanism go into a metal on metal clinking frenzy...repaired. Then the strap clip breaks....repaired, then before that the left volume slider wants to be all grabby....fixed, then the tape player started to play too slow after adjustments.....fixed again, then the stereo indicator didn't want to work...adjusted VR31....fixed, then the main power leaf switch didn't want to make connection when turned on.....fixed, then while playing a tape left channel drops..dirty function switch....fixed, then it would keep stopping while playing a tape...narrowed that down to a sticking tape counter that would trip the stop circuit solenoid.

It's all getting fixed but damn.....she's a demanding little b***h. But when it's working I'm on cloud nine

Anyone else with a box like this? Does it ever get better or worse?

These things are just old. And the longer they sit without use, the more of these gremlins grow into them. Who knows how long that radio sat idle before you got it and now it's getting warm and cold, warm and cold, plastic has shrunk, parts are flexing and moving and as the miles click by, most of these "almost broken" parts are gonna pop.

These things are just old. And the longer they sit without use, the more of these gremlins grow into them. Who knows how long that radio sat idle before you got it and now it's getting warm and cold, warm and cold, plastic has shrunk, parts are flexing and moving and as the miles click by, most of these "almost broken" parts are gonna pop.

I'm also getting old - so I'll not be gyrating or flopping around like a dead Turkey in a clothes dryer these days for any reason!

I'm also getting old - so I'll not be gyrating or flopping around like a dead Turkey in a clothes dryer these days for any reason!

My alka selzer tablet jingle goes....plop / plop - fizz / fizz - what a PITA it is

My alka selzer tablet jingle goes....plop / plop - fizz / fizz - what a PITA it is