Ugh... that's a really really cheap volume pot. Ok, let me tell you what I think is going on here.

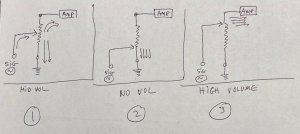

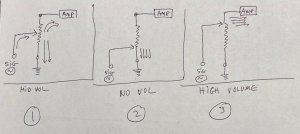

Consider how a (simple) normal pot is supposed to work in an audio situation.

In example #1, the signal enters the mid point of the pot. Some signal will get shunted to ground, and some signal gets sent to the amplifier to be output to speakers. In example #2, the signal enters the bottom of the pot and with little resistance to ground, most if not all of the signal gets sent to ground with non or little going to the amp, result in no volume. Example #3 shows what happens when the volume pot is at max, signal enters the end of the resistor, so most all signal goes to the amp. The signal would have to travel through the entire resistor in order to reach ground so it takes the easier path to the amplifier. Result, max amp signal.

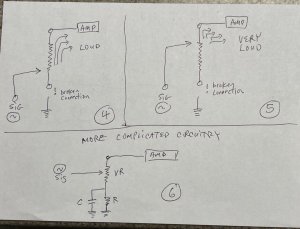

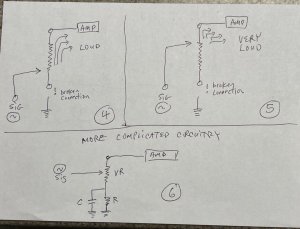

In example #4, you will see that in the case where there is a broken connection at the circuitry that connects to ground... what happens is that even with the pot set to minimum, all of the signal will be routed to the amplifier, although the signal will see resistance, that path is still much easier to traverse than the path to ground which in this example is broken. So the signal is slightly attenuated to the amplifier, but it will still result in significant volume at the amplifier. Then consider example #5, with the same broken ground and the volume control set to maximum. Once again, all the signal gets to the amplifier but without the resistance element to block it, so the amplifier gets full volume, even more than if the ground circuit was unbroken, which if integrity was kept, would still result in a slight amount of signal getting shunted to ground. Result: ultra loud. In #4 and #5, the volume control was set to minimum and maximum but in both cases, the volume at the amp will be high, although higher with the setting at maximum since although current will be reduced in the minimum position because the signal has to go through the resistor, voltage will still be high.

In the last example, this is probably reserved for very complex circuits, in which other components are at play for various reasons. This scenario is almost certainly not the case because in a simple boombox like this, they would never need to insert other components that adds costs and complexity. The name of the game on cheap boombox is simple and cheap. But if in this case, the resistor was open or the capacitor shorted, that could have some affect on the signal. For the purposes of this boombox, just ignore that this example is even presented here.

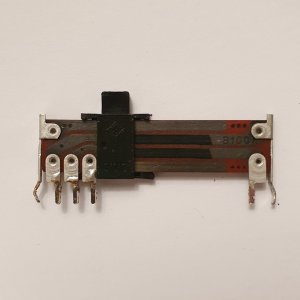

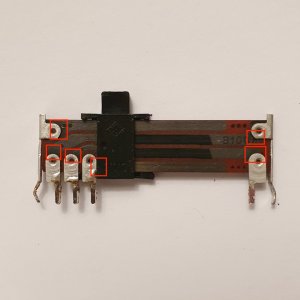

What could be wrong with your control? My educated guess is that the rivets that connects the resistor tracts have broken. You can confirm this with your DMM. Luckily, you can also fix this pretty easily with conductive epoxy. Use only enough and don't spread it too far off track otherwise you could cause shorts or change the resistance curve. A little change probably won't be noticeable. These epoxies aren't cheap but you don't need a lot and they don't have good shelf life so just buy what you need, no more. Also make sure they are properly cured before use. Conductive epoxies aren't conductive or fully conductive until they've cured. Some requires heat curing.... this may involve a short time in the oven. Don't worry, just don't tell your wife, she won't know. It's not like you are trying to bake an automotive cylinder head.