Hello fellow boombox lovers!

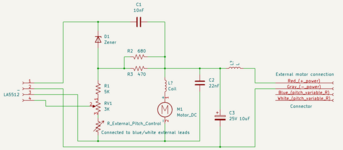

I recently purchased M-X960K in great cosmetic condition. However it was not working at all when I bought it and after I replaced blown fuse radio section started to work. Cassette deck wouldn't react to any button presses. Quick voltage check at motor terminals indicated that power is being delivered to the motor which meant that something is wrong with capstan motor. It is a 4 terminal capstan motor with external pitch control resistor (rotary on the front panel). After taking capstan motor apart I discovered that cylinder that I thought is the motor itself is just an external shell with PCB and actual motor inside. There was an obviously burnt component on the PCB. I was lucky that marking on it was still legible and couple of weeks later I had few replacement LA5512 delivered. I soldered the new IC and put everything back together. Motor was now spinning and casette mechanism was mostly working. I used a bluetooth casette adapter for test purpose. I've not used cassette players for a very long time and frankly I was underwhelmed by the audio quality. However this was not the main issue. Motor was getting quite hot very quickly which was concerning. I got busy with other priorities and abandoned my little project for a while. Few weeks ago I decided to dig a bit deeper and try to identify the root cause of the motor getting hot. I've ordered a 3000hz test tape to check capstan speed. Using test tape I got around 4500-5000Hz which I couldn't fully adjust using both pitch control knob and variable resistor on the motor control PCB. Then I decided to test motor parameters and it certainly doesn't look alright, especially temperature and current consumption.

Voltage on the motor terminals: 10.5V

Current consumption: 0.6A

Control IC temperature: Heated from 25degC to 80degC in 1 minute.

Motor armature heated to 60degC within 1 minute of operating time.

Winding resistance: 6.1Ohm, 6.3ohm, 9.2ohm.

Armature winding looks discolored. Can I conclude that this motor is cooked and need to be replaced?

If yes, what kind of motor can I replace it with?

shaft diameter d 2mm

shaft total length L 37mm

shaft protrusion l 10mm

inner can outer D 32mm

inner can length L 22mm

outer can inner d 35mm

outer can outer D 38mm

outer can length L 36mm

I recently purchased M-X960K in great cosmetic condition. However it was not working at all when I bought it and after I replaced blown fuse radio section started to work. Cassette deck wouldn't react to any button presses. Quick voltage check at motor terminals indicated that power is being delivered to the motor which meant that something is wrong with capstan motor. It is a 4 terminal capstan motor with external pitch control resistor (rotary on the front panel). After taking capstan motor apart I discovered that cylinder that I thought is the motor itself is just an external shell with PCB and actual motor inside. There was an obviously burnt component on the PCB. I was lucky that marking on it was still legible and couple of weeks later I had few replacement LA5512 delivered. I soldered the new IC and put everything back together. Motor was now spinning and casette mechanism was mostly working. I used a bluetooth casette adapter for test purpose. I've not used cassette players for a very long time and frankly I was underwhelmed by the audio quality. However this was not the main issue. Motor was getting quite hot very quickly which was concerning. I got busy with other priorities and abandoned my little project for a while. Few weeks ago I decided to dig a bit deeper and try to identify the root cause of the motor getting hot. I've ordered a 3000hz test tape to check capstan speed. Using test tape I got around 4500-5000Hz which I couldn't fully adjust using both pitch control knob and variable resistor on the motor control PCB. Then I decided to test motor parameters and it certainly doesn't look alright, especially temperature and current consumption.

Voltage on the motor terminals: 10.5V

Current consumption: 0.6A

Control IC temperature: Heated from 25degC to 80degC in 1 minute.

Motor armature heated to 60degC within 1 minute of operating time.

Winding resistance: 6.1Ohm, 6.3ohm, 9.2ohm.

Armature winding looks discolored. Can I conclude that this motor is cooked and need to be replaced?

If yes, what kind of motor can I replace it with?

shaft diameter d 2mm

shaft total length L 37mm

shaft protrusion l 10mm

inner can outer D 32mm

inner can length L 22mm

outer can inner d 35mm

outer can outer D 38mm

outer can length L 36mm