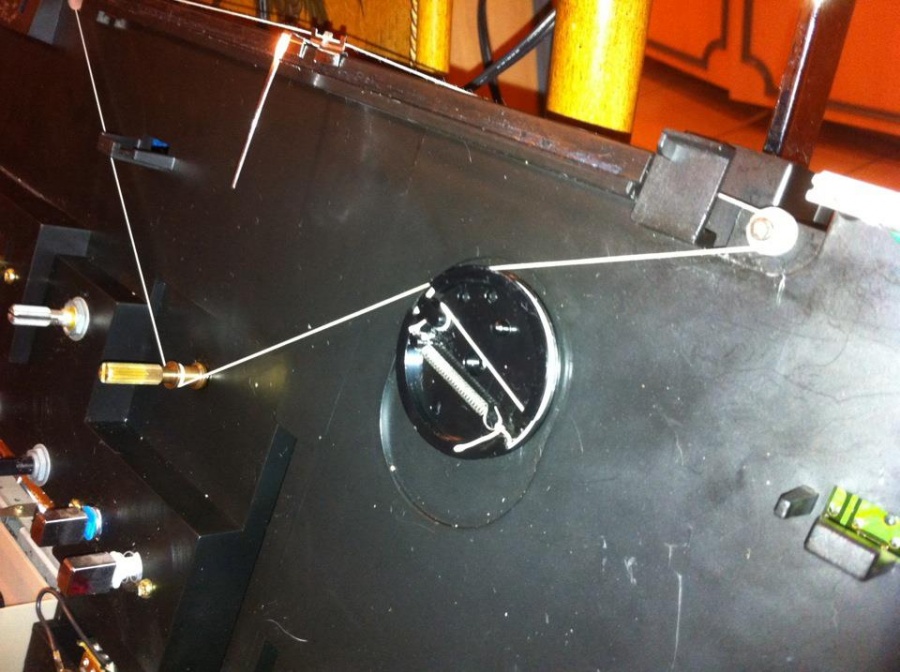

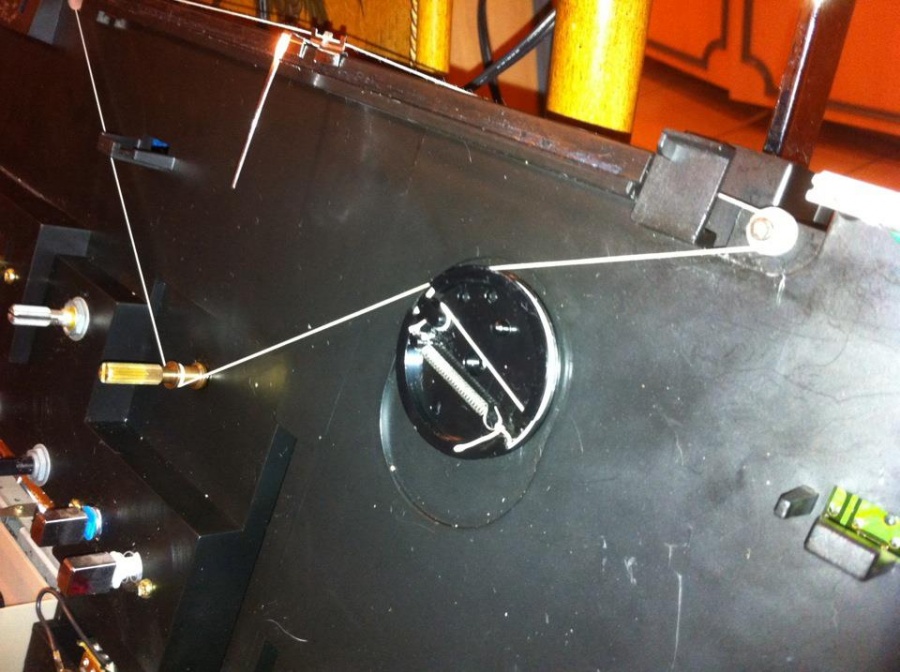

I received a boombox recently that had a little shipping damage. The tuner string, guide wheel was broken from the plastic peg from where it was attached. The tuner dial was not functioning as result. First thing was rigging a new anchor for the guide wheel. The original was just a plastic peg which was broken flush from the chasis. I drilled it out and used a phono cartridge screw as an anchor. It was perfect size for the guide wheel and a couple washers.

It took a little while to figure out how to reset the tuning string-it only goes on one way. I tried several different combinations with the string until the movement and slack was correct. The hard part was getting the string set over the guide wheel. In order to achieve enough slack you have to expand the spring on the tuning pully.

A couple things before reassembly; calibrate the tuning needle in accordance with the proper station and tuning scale. This is easy as the tuning needle can be adjusted by simply sliding it left or right on the string until it lines up with the scale and proper station. Lastly, clean any finger prints and dust from the tuning scale, tuning needle, glass and all visible parts before reassembling (it sucks going through disassembly and reassembly to realize your tuner window is dirty from the inside-hehe). It's an easy last minute thing before reassembly. Tuner is now functioning properly.

It took a little while to figure out how to reset the tuning string-it only goes on one way. I tried several different combinations with the string until the movement and slack was correct. The hard part was getting the string set over the guide wheel. In order to achieve enough slack you have to expand the spring on the tuning pully.

A couple things before reassembly; calibrate the tuning needle in accordance with the proper station and tuning scale. This is easy as the tuning needle can be adjusted by simply sliding it left or right on the string until it lines up with the scale and proper station. Lastly, clean any finger prints and dust from the tuning scale, tuning needle, glass and all visible parts before reassembling (it sucks going through disassembly and reassembly to realize your tuner window is dirty from the inside-hehe). It's an easy last minute thing before reassembly. Tuner is now functioning properly.

. I agree with "Superduper", messing around with a tuning string the way I have is not recommended. My intensions were to simply change the pin and reassemble the guide wheel. During the repair the tuning string became unraveled. At this point i figured I might as well reasemble the box and just leave the tuner not working as it was.

. I agree with "Superduper", messing around with a tuning string the way I have is not recommended. My intensions were to simply change the pin and reassemble the guide wheel. During the repair the tuning string became unraveled. At this point i figured I might as well reasemble the box and just leave the tuner not working as it was.