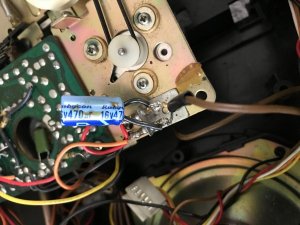

I got a new mini box in the mail and of course issues with the cassette deck. Near the end of a quick maintenance run through, I started to clean the pinch roller. After about 30 q-tips (both sides), the black stuff wasn't getting any lighter. I tried a little fine sand paper to see if that would help, and it got more gunk off. Then I went back to cleaning with Q-tips and went through another 20. The dirt on the q-tip doesn't seem to be getting any lighter, making me wonder will this ever end?

I will admit the sound is getting much better. Should I keep cleaning until there is no more black gunk coming off the roller?! Just wondering if this is normal as this seems like a sh*t load of q-tips. About an hour into cleaning the roller and not even finished!

Thanks

Mike

I will admit the sound is getting much better. Should I keep cleaning until there is no more black gunk coming off the roller?! Just wondering if this is normal as this seems like a sh*t load of q-tips. About an hour into cleaning the roller and not even finished!

Thanks

Mike

5W30 motor oil from the nearest gas station is the one i still have to get into my collection

5W30 motor oil from the nearest gas station is the one i still have to get into my collection