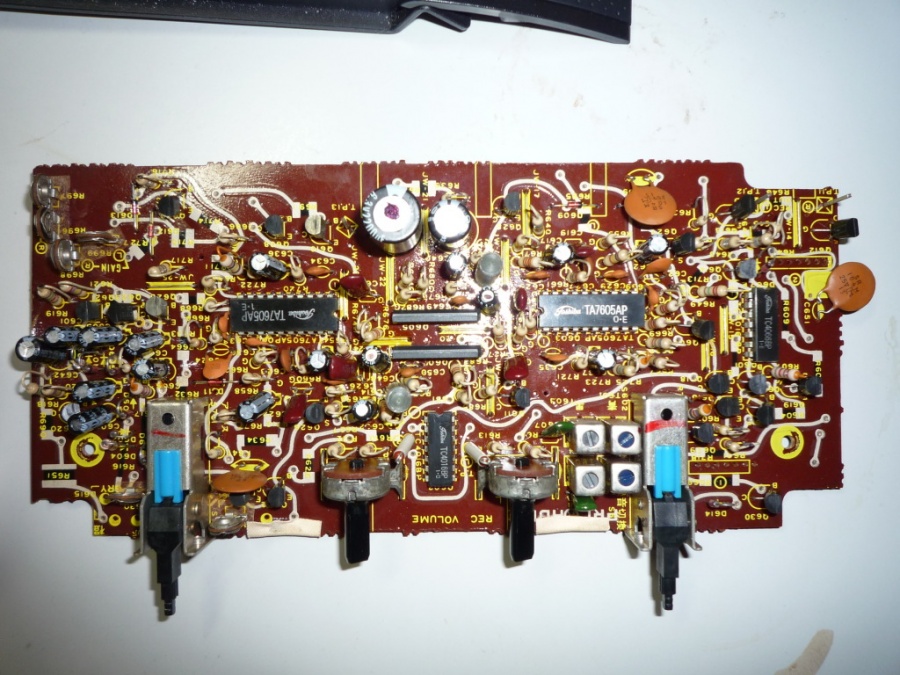

I really don't think the IC's will "sing." These IC's look to be very low signal type of chips, and they are encased in epoxy. Rather than doing a shotgun approach and replacing everything on that board, which in itself could cause problems by inroducing changes to the signal characteristics, requiring readjustments/realignments, I suggest you take a step back and reassess your approach. If you truly feel that a component on your board is singing, then perhaps you can try probing with a stethescope. There are automotive type stethescopes that uses a needle type probe which can help you narrow it down. Also, I would expect capacitors and coils, and maybe diodes and transistors to produce this noise way before I would suspect IC's. When you replaced the caps, you are only talking about electrolytics right? Every component has slight variations in characteristics. See all those adjustment points on the board including the transformers? Well, usually, everything is adjusted and calibrated after a board is populated. If you replaced everything, finding the documentation to recalibrate everything on a japan only model will be an even harder task than finding a single bad component.

If you ask me, I think you will find the single greatest probability of failure on that board to be the printed (white colored) jumpers on that board. They are extremely prone to failure. You say you checked the resistors. But did you know that connected to those painted traces are printed resistors too? Yes, they too are highly prone to failure. I tell you this from experience. The IC's are the last things I would suspect. Not that they don't go bad, but I say check the other stuff first. Oh, and BTW, those printed resistors? Without service documentation, it's almost impossible to know what the printed "value" is. So you almost HAVE to have a fully working one to check against.

What do they use to activate recording?

What do they use to activate recording? maybe a possible bad connection or ground as I have had this issue with one of my Lasonic playback heads

maybe a possible bad connection or ground as I have had this issue with one of my Lasonic playback heads