If you've lost segments of your JVC PC-55 / PC-550 LCD display, and unless something basic and obvious like edge of the ribbon where a single connection point was lost and you can restore contact with a small piece of adhesive/tape, I'm declaring the JVC PC-55 LCD display currently irreparable.

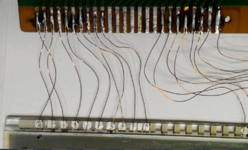

- The ribbons are 40 years old range now, and as such very delicate.

- Bends and scratches on the ribbon can create brakes in continuity of the traces.

- Any attempts at pulling it off to reattach it with something like 3M Z-Axis Conductive Tape is very risky and likely to damage the ribbon further, contact points on the ribbon as you remove it first for reattachment, etc. and no guarantee you won't loose further connections in addition to not fixing the ones that are already failed.

- I have tried conductive paint to try and get contacts back, and it did not help things on this ribbon.

- On the LCD display side, the fragility of the attachment points on either side and narrowness of the attachment area make this like heart surgery. There is also risk you can damage the contact points on the LCD glass surface.

- Out of the factory the ribbons are secured with clear scotch tape in a few areas - on the LCD side and some boards. Attempts to remove this old sticky glue tape prior to attempts to reattach the ribbons may rip conductive tracks on the ribbons, rip the ribbon, damage contact points etc. Event cutting this tape with a blade is very risky to the ribbon.

Re: Backlight

Since the aging of the elements involved like ribbon, glue, etc. make the whole area delicate to work in, if you have burned out fuse type 12v bulbs in your display, I suggest not attempting to bend the plastic tabs that secure the bulb circuit board all gently and gingerly to preserve the tabs. This white back light cone plastic is now old and brittle and it will not bend easily, and when it gives it will just likely break and run your tool into the ribbon with uncontrolled force, disturb it and potentially damage it. Why fight to preserve two plastic tabs you never see at a risk to the ribbons and LCD display you always look at? Instead, with needle nose pliers reach down and break two of the tabs toward middle of the board on one side of the board to free up the light circuit board removal. Also note, pulling the board up after taking it out of the back may apply forces to the ribbons running around it through the two 12v wires on the bottom of the board. I suggest you remove the deck's black metal bottom secured with two screws in the bottom of plastic deck face in corners, and three screws at back of circuit board, where the one next to the battery compartment connectors has a ground wire under the screw. Once you remove this bottom on the bottom of the circuit board you can unwind the red/black12v wire to give yourself more slack and freedom to move the lightbulb board up and out of the back of the display to switch the bulbs without pulling the delicate ribbons as you're doing so. JVC left us room on the 12V light bulbs board wire, but twisted it and tucked it away on the bottom of the board. Use this slack to not disturb the ribbons when replacing boards. If you damage your LCD elements ribbons, it will brake your heart.

If someone has repaired a JVC PC-55 missing elements Deck LCD display ribbon issues successfully, please share your method with us all to help preserve these 55s/550s.

For those of you who have damaged LCD elements, don't throw these boomboxes out, perhaps a solution will be found of some sort.

I know this is sad to say. Maybe we'll figure it out. Maybe someone will make new replacement ribbons that address this issue? I currently don't see any other way to successfully restore display function once these ribbons and their contact points are compromised.

- The ribbons are 40 years old range now, and as such very delicate.

- Bends and scratches on the ribbon can create brakes in continuity of the traces.

- Any attempts at pulling it off to reattach it with something like 3M Z-Axis Conductive Tape is very risky and likely to damage the ribbon further, contact points on the ribbon as you remove it first for reattachment, etc. and no guarantee you won't loose further connections in addition to not fixing the ones that are already failed.

- I have tried conductive paint to try and get contacts back, and it did not help things on this ribbon.

- On the LCD display side, the fragility of the attachment points on either side and narrowness of the attachment area make this like heart surgery. There is also risk you can damage the contact points on the LCD glass surface.

- Out of the factory the ribbons are secured with clear scotch tape in a few areas - on the LCD side and some boards. Attempts to remove this old sticky glue tape prior to attempts to reattach the ribbons may rip conductive tracks on the ribbons, rip the ribbon, damage contact points etc. Event cutting this tape with a blade is very risky to the ribbon.

Re: Backlight

Since the aging of the elements involved like ribbon, glue, etc. make the whole area delicate to work in, if you have burned out fuse type 12v bulbs in your display, I suggest not attempting to bend the plastic tabs that secure the bulb circuit board all gently and gingerly to preserve the tabs. This white back light cone plastic is now old and brittle and it will not bend easily, and when it gives it will just likely break and run your tool into the ribbon with uncontrolled force, disturb it and potentially damage it. Why fight to preserve two plastic tabs you never see at a risk to the ribbons and LCD display you always look at? Instead, with needle nose pliers reach down and break two of the tabs toward middle of the board on one side of the board to free up the light circuit board removal. Also note, pulling the board up after taking it out of the back may apply forces to the ribbons running around it through the two 12v wires on the bottom of the board. I suggest you remove the deck's black metal bottom secured with two screws in the bottom of plastic deck face in corners, and three screws at back of circuit board, where the one next to the battery compartment connectors has a ground wire under the screw. Once you remove this bottom on the bottom of the circuit board you can unwind the red/black12v wire to give yourself more slack and freedom to move the lightbulb board up and out of the back of the display to switch the bulbs without pulling the delicate ribbons as you're doing so. JVC left us room on the 12V light bulbs board wire, but twisted it and tucked it away on the bottom of the board. Use this slack to not disturb the ribbons when replacing boards. If you damage your LCD elements ribbons, it will brake your heart.

If someone has repaired a JVC PC-55 missing elements Deck LCD display ribbon issues successfully, please share your method with us all to help preserve these 55s/550s.

For those of you who have damaged LCD elements, don't throw these boomboxes out, perhaps a solution will be found of some sort.

I know this is sad to say. Maybe we'll figure it out. Maybe someone will make new replacement ribbons that address this issue? I currently don't see any other way to successfully restore display function once these ribbons and their contact points are compromised.