Yes I cheated today. Not on my wife but I had to operate on Goldie.

As you guys know I pulled Grand Master C out and stretched its legs. Everything was going smoothly while playing a tape but then out of the corner of my eye I thought I noticed something odd. It looked as if my tape run indicator hesitated. Now fully engaged I am now up close and keeping a watchful eye on it.

Could it be that I imagined it......Hell NO!!! I can't ever get that lucky! :annoyed: Sure enough its freezing up every now and then. Tape counter is working great though.

:annoyed: Sure enough its freezing up every now and then. Tape counter is working great though.

All I can think about is how I am not looking forward to tearing this thing down to bare bones to look things over but also knowing full well that this is going to drive me nuts unless I fixed it. Pulled the back off and looked at all the work that lied ahead of me. I started brainstorming. Hmmm. Might be a stretched belt. Looks like much of it is under the circuit board for the lower deck. Next I opened the cassette door. Hmm. Enough room to fish the belt out around the spindle.

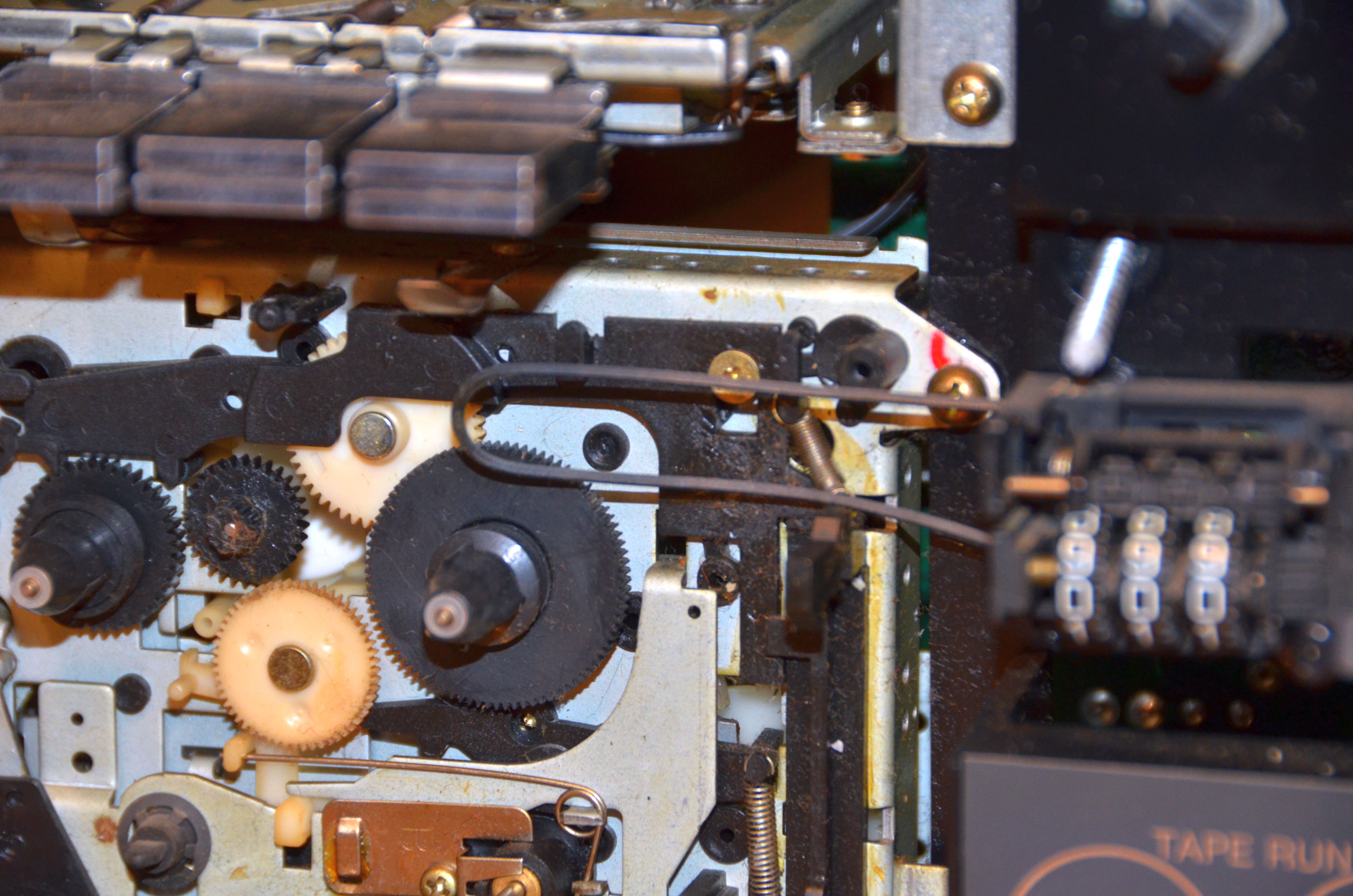

Ok....Attack mode. Lets cheat!!! Loosened the lower deck board and folded it out of the way. With the help of a pick and my assorted new belt assortment I was done in 15 minutes flat with a fresh replacement belt.

Guess the belt had stretched just enough to not turn the tape run indicator pulley correctly. She's all good now. A picture of me squirming the belt past the front cover of the box housing inside the cassette bay. This really is a better way to go IMO. Beats the alternative. Easier than I thought and much better than labeling wires and making a career out of it...

As you guys know I pulled Grand Master C out and stretched its legs. Everything was going smoothly while playing a tape but then out of the corner of my eye I thought I noticed something odd. It looked as if my tape run indicator hesitated. Now fully engaged I am now up close and keeping a watchful eye on it.

Could it be that I imagined it......Hell NO!!! I can't ever get that lucky!

:annoyed: Sure enough its freezing up every now and then. Tape counter is working great though.

:annoyed: Sure enough its freezing up every now and then. Tape counter is working great though.All I can think about is how I am not looking forward to tearing this thing down to bare bones to look things over but also knowing full well that this is going to drive me nuts unless I fixed it. Pulled the back off and looked at all the work that lied ahead of me. I started brainstorming. Hmmm. Might be a stretched belt. Looks like much of it is under the circuit board for the lower deck. Next I opened the cassette door. Hmm. Enough room to fish the belt out around the spindle.

Ok....Attack mode. Lets cheat!!! Loosened the lower deck board and folded it out of the way. With the help of a pick and my assorted new belt assortment I was done in 15 minutes flat with a fresh replacement belt.

Guess the belt had stretched just enough to not turn the tape run indicator pulley correctly. She's all good now. A picture of me squirming the belt past the front cover of the box housing inside the cassette bay. This really is a better way to go IMO. Beats the alternative. Easier than I thought and much better than labeling wires and making a career out of it...