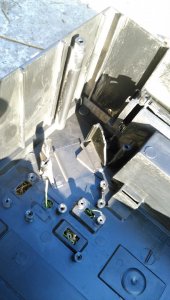

Argh. Lasonic L30 transformer housing broken in post

- Thread starter Van Presence

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

jimmyjimmy19702010

Member (SA)

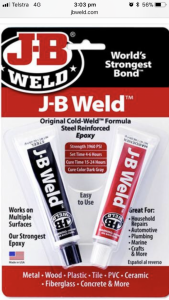

Internal repairs are easier as you’re not as worried about appearance. I’d use a generous amount JB weld in and around all the breaks - you’ll need to leave it for around 24 hrs plus before you stress it. Lightly sand and completely clean all of the areas to be adhered.

Cooler weather is better as the JB weld will stiffen up and will be easier to work.

None of my JB weld repairs have ever let go.

Cooler weather is better as the JB weld will stiffen up and will be easier to work.

None of my JB weld repairs have ever let go.

Lasonic TRC-920

Moderator

Yeah, What Jimmy said.

If you have all the bits and pieces, I would glue them back into too.

You'll get her back up and running!

If you have all the bits and pieces, I would glue them back into too.

You'll get her back up and running!

jimmyjimmy19702010

Member (SA)

Ok, in that case, use a little super glue to temporarily ‘assemble’ the pieces, one or two pieces at a time allowing the glue to dry before adding the next piece/pieces. Use just enough to bond the pieces, don’t allow any super glue to run out of the joined pieces. (On its’ own, super glue isn’t a permanent fix, it’s just used to hold everything in place).

Once you’ve checked for alignment of the assembled bits and the super glue is dry, smother the glued bits and pieces with JB Weld ensuring you haven’t applied weld to areas that are going to cause reassembly issues.

Many of my previous JB Weld repair projects have required the use of super glue for the initial assembly.

BTW, don’t worry about the strength of the repaired area, it will be much stronger than the rest of the case! Also, ensure no JB Weld gets inside the screw post holes - you’ll need a drill to get it out if you do! Don’t worry if a little super glue gets inside during the assembly process.

Hey, at least you have the pieces you need to reassemble!!

I’d be inclined to reinforce the transformer posts with JB Weld on any Lasonic you’re shipping.

Once you’ve checked for alignment of the assembled bits and the super glue is dry, smother the glued bits and pieces with JB Weld ensuring you haven’t applied weld to areas that are going to cause reassembly issues.

Many of my previous JB Weld repair projects have required the use of super glue for the initial assembly.

BTW, don’t worry about the strength of the repaired area, it will be much stronger than the rest of the case! Also, ensure no JB Weld gets inside the screw post holes - you’ll need a drill to get it out if you do! Don’t worry if a little super glue gets inside during the assembly process.

Hey, at least you have the pieces you need to reassemble!!

I’d be inclined to reinforce the transformer posts with JB Weld on any Lasonic you’re shipping.

samovar

Member (SA)

Exactly the same kind of accident happened to me with a TRC 920. The transofrmer tends to break in all Lasonics and it hammers the plastic case from the inside. As a result, the plastic breaks in "explosive" mode, but all the micropieces are (or should be) available, if the parcel is not damaged.

As Chris has correctly pointed out, you need to glue all the parts together FIRST. Only THEN you can put the resulting piece of plastic in place and make it fit the hole. Try to salvage as many bits and tits as possible, you can always deal with the resulting microholes AFTER you collate the pieces until you get one.

You'll be surprised by the way the case will "click" in place! Best of luck and keep us posted on the progress of your restoration.

As Chris has correctly pointed out, you need to glue all the parts together FIRST. Only THEN you can put the resulting piece of plastic in place and make it fit the hole. Try to salvage as many bits and tits as possible, you can always deal with the resulting microholes AFTER you collate the pieces until you get one.

You'll be surprised by the way the case will "click" in place! Best of luck and keep us posted on the progress of your restoration.

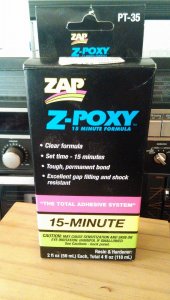

Hmm JB weld. Don't have that, but got this for my 920 (got rebroken 24hrs after using it so not sure if worked)jimmyjimmy19702010 said:Ok, in that case, use a little super glue to temporarily ‘assemble’ the pieces, one or two pieces at a time allowing the glue to dry before adding the next piece/pieces. Use just enough to bond the pieces, don’t allow any super glue to run out of the joined pieces. (On its’ own, super glue isn’t a permanent fix, it’s just used to hold everything in place).

Once you’ve checked for alignment of the assembled bits and the super glue is dry, smother the glued bits and pieces with JB Weld ensuring you haven’t applied weld to areas that are going to cause reassembly issues.

Many of my previous JB Weld repair projects have required the use of super glue for the initial assembly.

BTW, don’t worry about the strength of the repaired area, it will be much stronger than the rest of the case! Also, ensure no JB Weld gets inside the screw post holes - you’ll need a drill to get it out if you do! Don’t worry if a little super glue gets inside during the assembly process.

Hey, at least you have the pieces you need to reassemble!!

I’d be inclined to reinforce the transformer posts with JB Weld on any Lasonic you’re shipping.

Is the jb stuff you're talking about the 2 part yellow syringe? Or the epoxy putty? The putty would help with the tiny missing bits, was quite a lot of that.

Bit annoying, it's the first postage break I've had and randomly the first lasonic not hand delivered.

jimmyjimmy19702010

Member (SA)

This is the specific JB Weld product I use:

https://www.ebay.com.au/i/400717850919

The two tubes contain a thick paste that is combined 50/50. One tube contains a black paste, the other contains a white paste. It is literally overkill for your repair project but you’ll know it’ll be fixed for good.

There are a lot of adhesive products out there that struggle with certain types of plastic. JB Weld seems to work on anything!

Just follow my advice re using super glue to temporarily hold all the separate bits together while the JB Weld cures.

https://www.ebay.com.au/i/400717850919

The two tubes contain a thick paste that is combined 50/50. One tube contains a black paste, the other contains a white paste. It is literally overkill for your repair project but you’ll know it’ll be fixed for good.

There are a lot of adhesive products out there that struggle with certain types of plastic. JB Weld seems to work on anything!

Just follow my advice re using super glue to temporarily hold all the separate bits together while the JB Weld cures.

caution

Member (SA)

Does it look like this one? PlasticWeld is a great epoxy for repairing plastic especially vinyl parts, or if you're missing chunks. If not, JVC nailed it with his suggestion of the Testor's model master solvent. A few well-placed drops and it saturates the crack surfaces. Wiggle them so it starts to squish out so you know it's fully welded. Takes a while to cure but is strong as new. Great for inside repairs where you don't care if you squirt out too much and runs or pools, leaving melt marks.Van Presence said:Is the jb stuff you're talking about the 2 part yellow syringe?

jimmyjimmy19702010

Member (SA)

Yep, same stuff in a more convenient package (more expensive though).caution said:Does it look like this one? PlasticWeld is a great epoxy for repairing plastic especially vinyl parts, or if you're missing chunks. If not, JVC nailed it with his suggestion of the Testor's model master solvent. A few well-placed drops and it saturates the crack surfaces. Wiggle them so it starts to squish out so you know it's fully welded. Takes a while to cure but is strong as new. Great for inside repairs where you don't care if you squirt out too much and runs or pools, leaving melt marks.Is the jb stuff you're talking about the 2 part yellow syringe?

samovar

Member (SA)

I use this (since you are in NZ, I provided the Australian link):

http://www.loctite-consumer.com.au/en.html

My two cents: the trick is not in the glue (which of course must be without solvent whatsoever and strong enough) but in the inside reinforcement you provide with some resin.

http://www.loctite-consumer.com.au/en.html

My two cents: the trick is not in the glue (which of course must be without solvent whatsoever and strong enough) but in the inside reinforcement you provide with some resin.

Trommelmops

Member (SA)

is it thinkable to renew the post? Im sad that you are in NZ.....if you would be here in the neighborhood i would have a look and im convinced that we could

fix it together.....Stronger than before I see no problems, like so often....

I see no problems, like so often....

fix it together.....Stronger than before

I see no problems, like so often....

I see no problems, like so often....Unbelievably, not 1 shop in Christchurch stocks JB plastic weld. Have to order from north island.

I'm using the model glue I've already got. First little bit done, seems good. Then get some of the jb putty to reinforce the base and screw posts.

I'm using the model glue I've already got. First little bit done, seems good. Then get some of the jb putty to reinforce the base and screw posts.

trippy1313

Member (SA)

jimmyjimmy19702010

Member (SA)

Looks pretty solid to me. It’ll certainly be much stronger than Mr Lasonic thought appropriate.

Hmm, should I have tried that? Reasonably confident it'll hold. If/when I sell it I'll try.trippy1313 said:Good work! Glad you got it back to work.

Did you test it by shaking it around good?

I'm happy with your sign of approval. I thought I'd stuffed up the re-solder of power cord because it didn't work. AC/DC switch sorted that outjimmyjimmy19702010 said:Looks pretty solid to me. It’ll certainly be much stronger than Mr Lasonic thought appropriate.

- Status

- Not open for further replies.