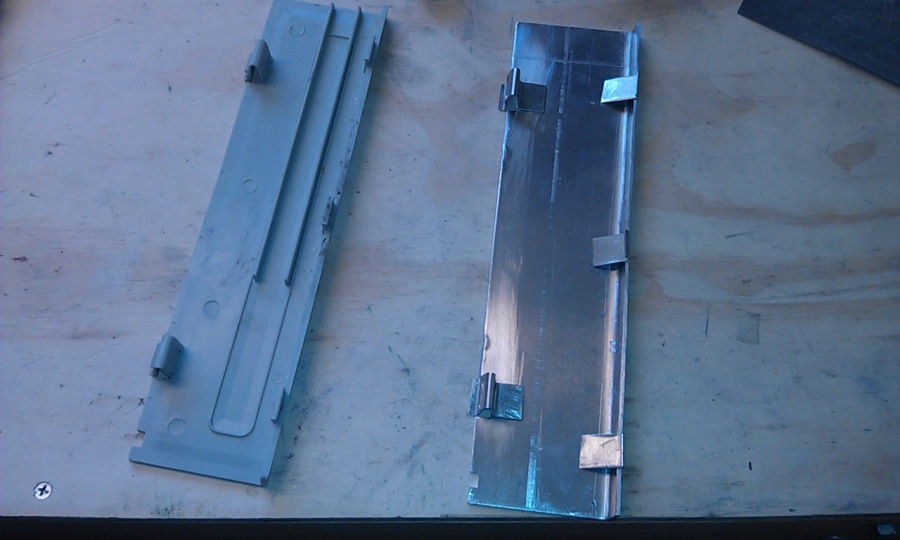

So, I created yet another battery door, this time for a Lasonic TRC-918. These are a bit more complicated and larger and I found that my small metal bender was not up to the challenge so I had to hand hammer it into shape which took a bit more time.

Also, this time around I figured out a better way to make the spring clips that hold the door closed, a way that does not use any pop rivets.

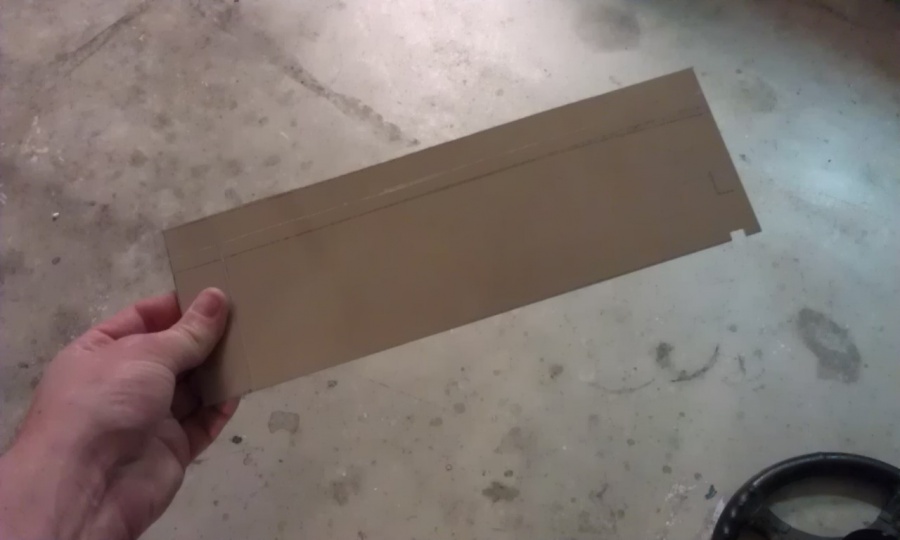

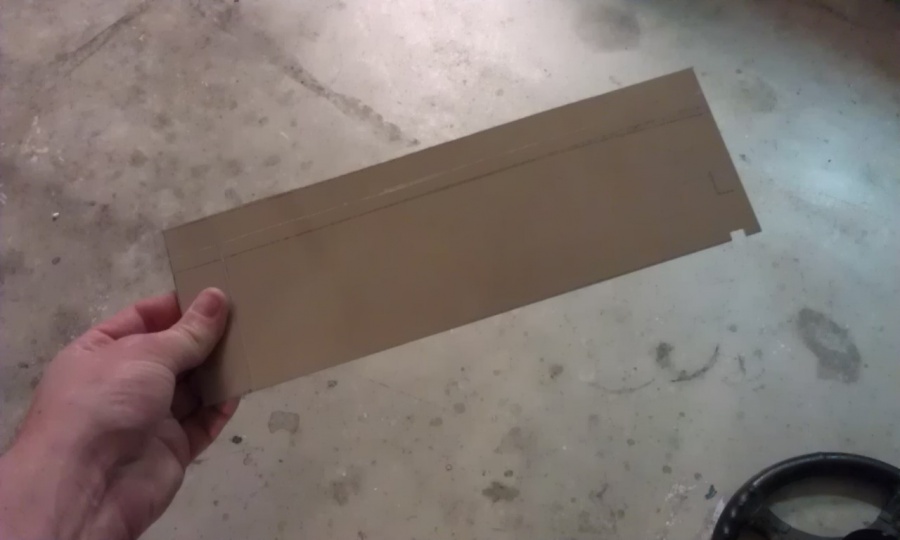

The first cut with the notch for the AC cord to hang out the door.

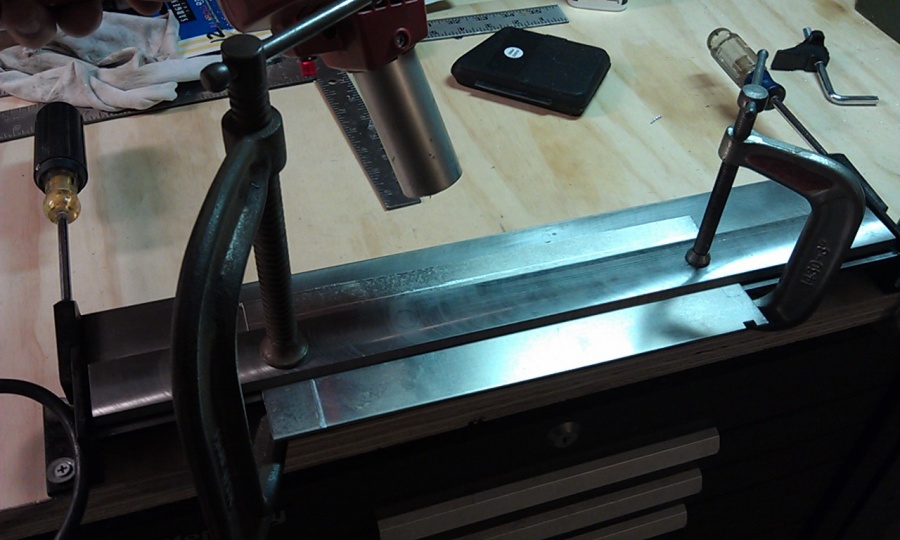

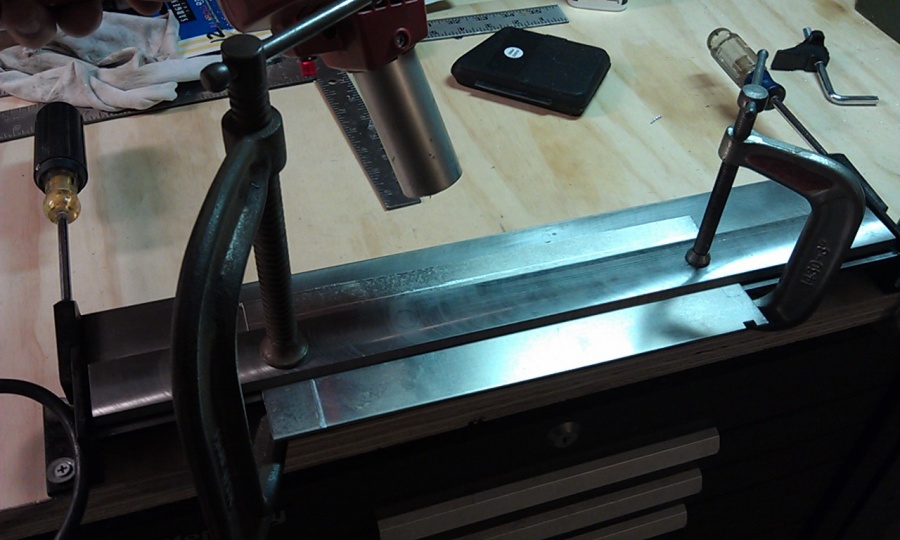

In the bender, I tried to heat the metal to get it to bend.

But...I ended up having to clamp it up in the vice and give it the "B.F.H."

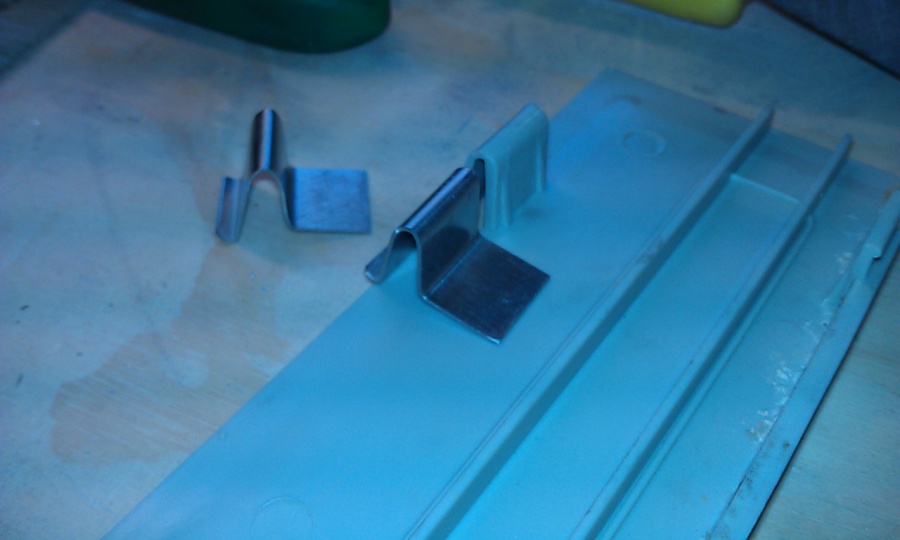

After some hammering and filing, I got it into the shape I wanted.

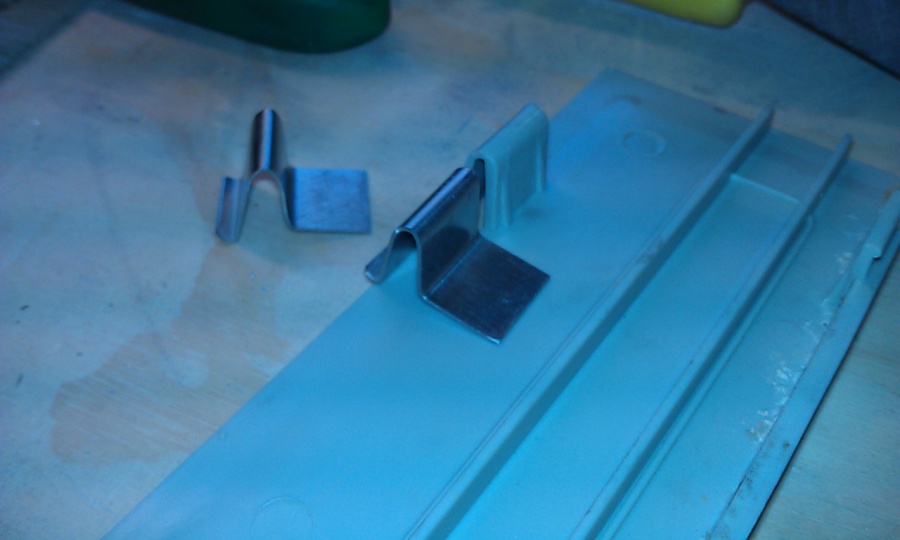

Now for the notches for the locking clips.

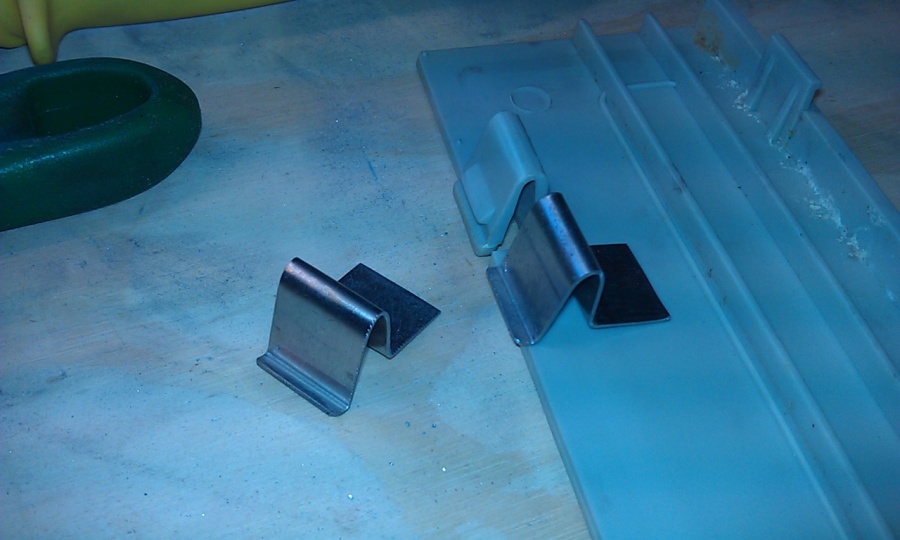

Making the locking clips....I'm getting better at making these...

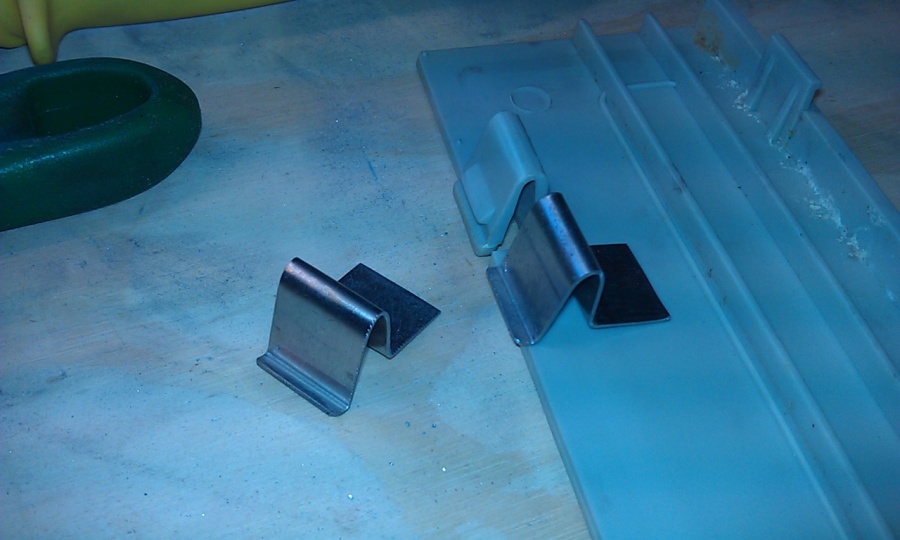

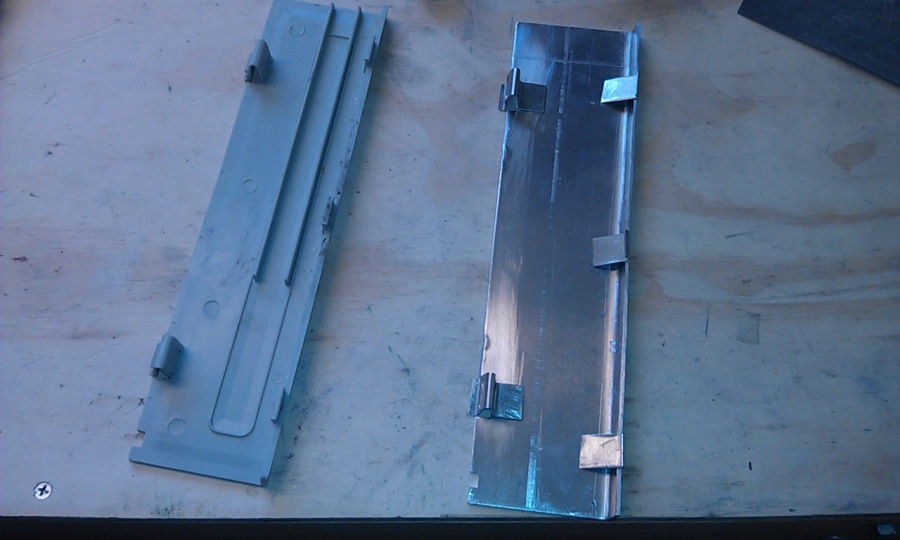

Here are all the pieces, including the bottom locking tabs

I'm very happy with the fit and finish on this one, even tighter than the last.

It still needs some sanding, but those are the parts....

The next thing I am doing that will be different from the Aiwa cover I made is, this one won't use rivets to hold the taps on. I have ordered an epoxy called Super Mend that I have used in the past. It is VERY strong and the goal is to BOND the pieces together so there will be no visible rivets on the outside. Once painted, it will look very close to the original.

There is about 5 1/2 - 6 hours into making one of these. I still have to make a few TRC-920 doors....but thankfully, the don't have any bends and no crazy angles! Just two spring clips and two tabs!

Also, this time around I figured out a better way to make the spring clips that hold the door closed, a way that does not use any pop rivets.

The first cut with the notch for the AC cord to hang out the door.

In the bender, I tried to heat the metal to get it to bend.

But...I ended up having to clamp it up in the vice and give it the "B.F.H."

After some hammering and filing, I got it into the shape I wanted.

Now for the notches for the locking clips.

Making the locking clips....I'm getting better at making these...

Here are all the pieces, including the bottom locking tabs

I'm very happy with the fit and finish on this one, even tighter than the last.

It still needs some sanding, but those are the parts....

The next thing I am doing that will be different from the Aiwa cover I made is, this one won't use rivets to hold the taps on. I have ordered an epoxy called Super Mend that I have used in the past. It is VERY strong and the goal is to BOND the pieces together so there will be no visible rivets on the outside. Once painted, it will look very close to the original.

There is about 5 1/2 - 6 hours into making one of these. I still have to make a few TRC-920 doors....but thankfully, the don't have any bends and no crazy angles! Just two spring clips and two tabs!

.

.