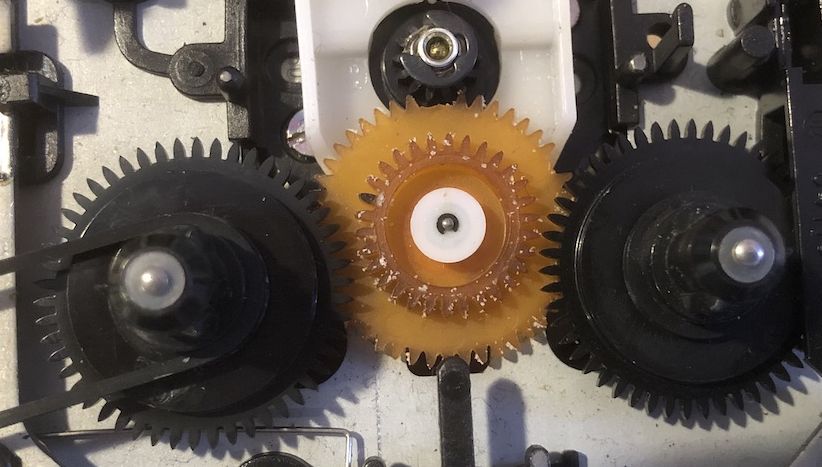

I was asked to see if I could reproduce a couple of deck gears that decayed. You know the ones, they're kinda rubbery to reduce vibrations, but the chemicals doing the softening escape over the years, reducing its strength to that of an almond - scrapes away and cracks apart very easily.

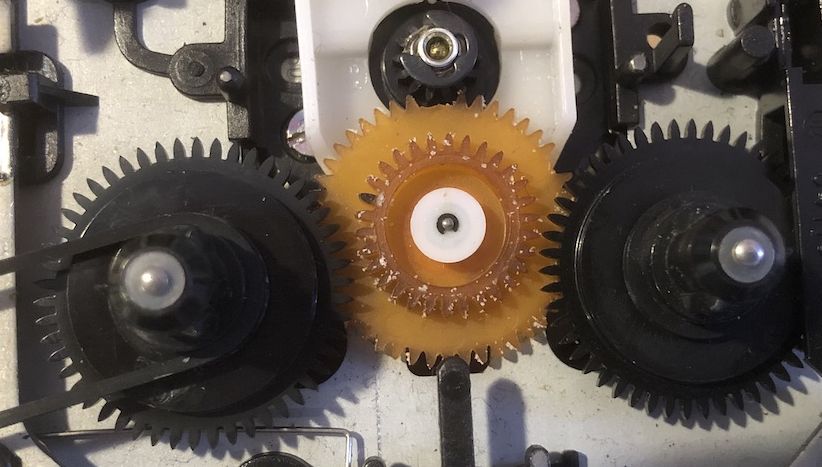

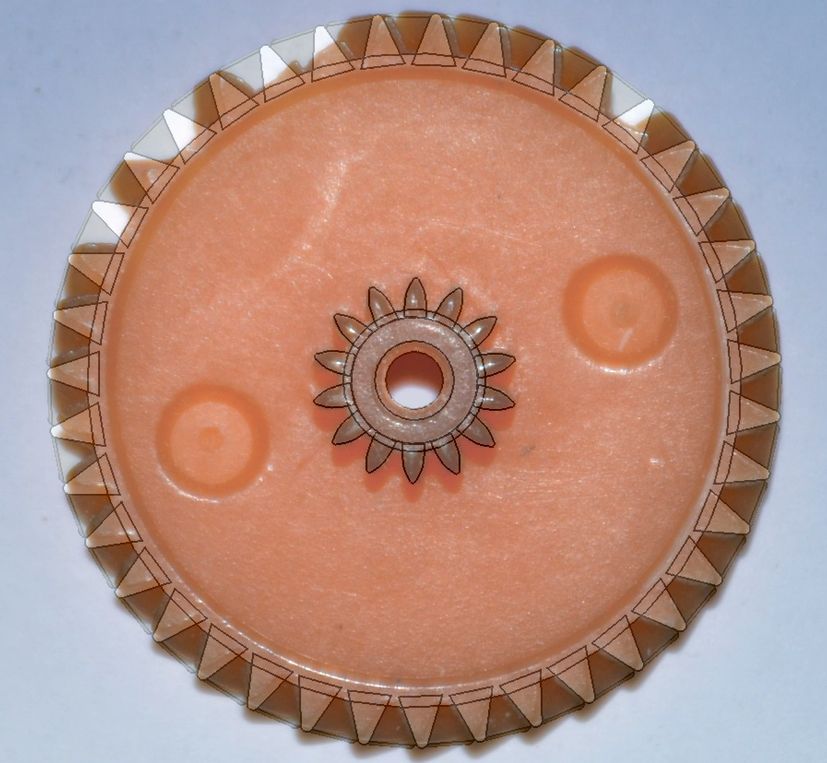

One broke during shipment despite excellent packing, but I got all measurements after reassembling it. A lot of time spent with a jewelers loupe and caliper, re-re-checking and adjusting until I zeroed in on something nice and close. I wasn't able to get their exact shape from any gear design tools, so I drew them manually, doing a 50/50 overlay with images to confirm. My camera aim isn't 100% straight so there's some perspective misalignment and sides of teeth visible, but still good enough to confirm. Based on how they're meshing in the first pic, it will be a close fit and may need adjustment if it ends up on the high side.

One broke during shipment despite excellent packing, but I got all measurements after reassembling it. A lot of time spent with a jewelers loupe and caliper, re-re-checking and adjusting until I zeroed in on something nice and close. I wasn't able to get their exact shape from any gear design tools, so I drew them manually, doing a 50/50 overlay with images to confirm. My camera aim isn't 100% straight so there's some perspective misalignment and sides of teeth visible, but still good enough to confirm. Based on how they're meshing in the first pic, it will be a close fit and may need adjustment if it ends up on the high side.