Greetings Everyone,

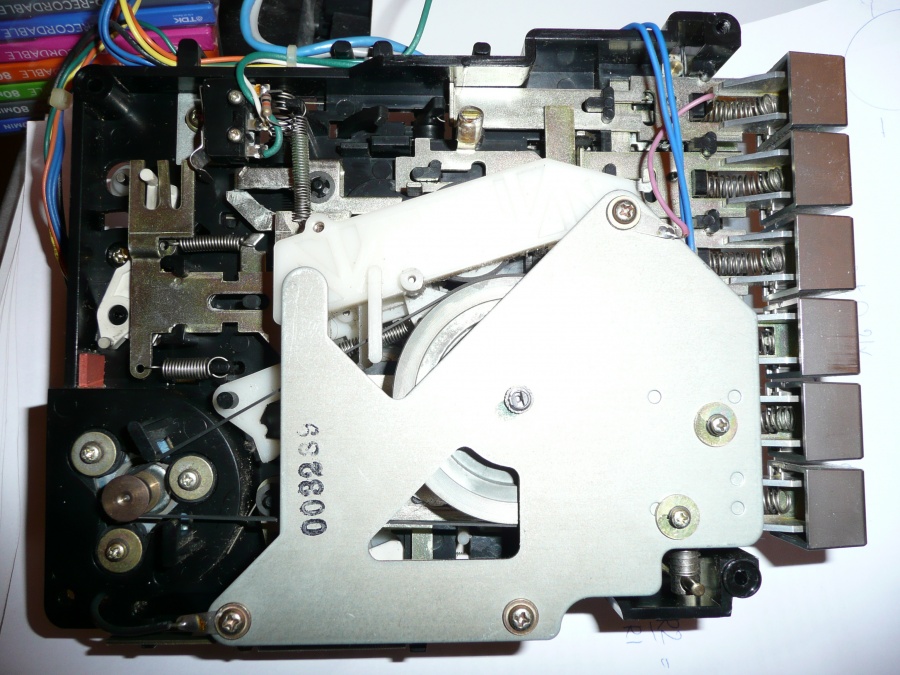

Just a quick one, I have replaced all the belts on a Sharp GF-9494. I can hear the motor works, but there is no turning when the play button is pressed. The play spool will try to turn when assisted, but gives up. I need to lubricate some areas I suspect as I have not done this yet. What lubrication do you suggest? I had a look in the recommended tools, did I see a name for a lube......? I am desperate to get this tape section fixed so I can have a complete GF-9494.

Your recommendations please.

Cheers

Brownlow

Just a quick one, I have replaced all the belts on a Sharp GF-9494. I can hear the motor works, but there is no turning when the play button is pressed. The play spool will try to turn when assisted, but gives up. I need to lubricate some areas I suspect as I have not done this yet. What lubrication do you suggest? I had a look in the recommended tools, did I see a name for a lube......? I am desperate to get this tape section fixed so I can have a complete GF-9494.

Your recommendations please.

Cheers

Brownlow

.

.