Hi all,

It’s been a few weeks since I posted anything. I have had some really helpful feedback on here so thought I would share what I have been up to.

I have been in search for a way to create my own decals for a boombox. This way you would be able to save even the roughest case and potentially bring it back to life by respraying and reapplying the original decal work. keeping true to the original spec. I did ask on here but I was surprised with the lack of comments, so get the impression not many people have taken on this challenge.

Not to be put off I continued my search. I mean these boomboxes were manufactured 40 years ago, surely I have the technology to recreate it. Well that’s what I thought anyway. So after a lot of searching I found what I think is a viable solution. When I say viable it doesn’t mean it’s easy and I nearly gave up several times. It was definitely a learning curve. But after several attempts and many expletives I think I have a method that I would certainly try again.

I can’t take the credit as I found the initial solution at https://pulsarprofx.com/

But this needed a bit of refinement.

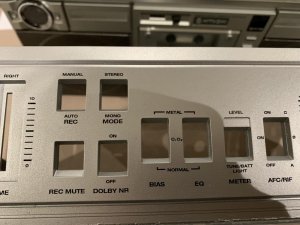

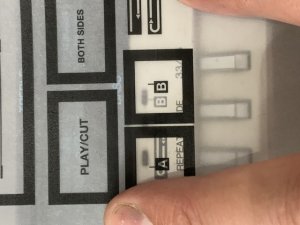

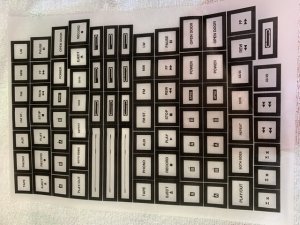

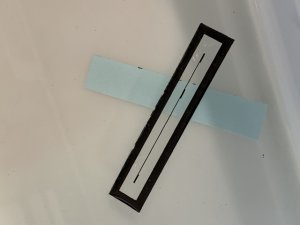

Anyway here are some pictures of a Hitachi TRK-8290 case that has been resprayed and new decals created and applied by myself. I have also included 3 pictures of an original TRK-8290 so you can compare the new decals with the old. Some are better than others, I was certainly getting better towards the end so practice definitely makes perfect.

Would really appreciate some feedback to see what you guys think. If it would be of interest to anyone happy to write up my experience and tips and share in here when I have some time.

It’s been a few weeks since I posted anything. I have had some really helpful feedback on here so thought I would share what I have been up to.

I have been in search for a way to create my own decals for a boombox. This way you would be able to save even the roughest case and potentially bring it back to life by respraying and reapplying the original decal work. keeping true to the original spec. I did ask on here but I was surprised with the lack of comments, so get the impression not many people have taken on this challenge.

Not to be put off I continued my search. I mean these boomboxes were manufactured 40 years ago, surely I have the technology to recreate it. Well that’s what I thought anyway. So after a lot of searching I found what I think is a viable solution. When I say viable it doesn’t mean it’s easy and I nearly gave up several times. It was definitely a learning curve. But after several attempts and many expletives I think I have a method that I would certainly try again.

I can’t take the credit as I found the initial solution at https://pulsarprofx.com/

But this needed a bit of refinement.

Anyway here are some pictures of a Hitachi TRK-8290 case that has been resprayed and new decals created and applied by myself. I have also included 3 pictures of an original TRK-8290 so you can compare the new decals with the old. Some are better than others, I was certainly getting better towards the end so practice definitely makes perfect.

Would really appreciate some feedback to see what you guys think. If it would be of interest to anyone happy to write up my experience and tips and share in here when I have some time.

Attachments

-

105.9 KB Views: 92

-

90.6 KB Views: 98

-

108.1 KB Views: 87

-

86.1 KB Views: 85

-

72.8 KB Views: 89

-

106.4 KB Views: 75

-

98.4 KB Views: 73

-

85.8 KB Views: 69

-

80 KB Views: 70

-

85.8 KB Views: 67

-

116.4 KB Views: 89