Here is an alternative to using contact cleaners on potentiometers. This way ensures you have removed the gunk and corrosion due to age.

I had an Aiwa mini box that would drop a channel at low to mid volume. At full volume both channels worked fine.

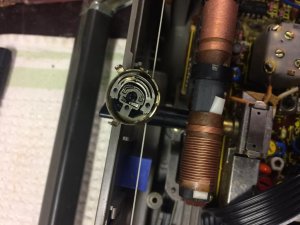

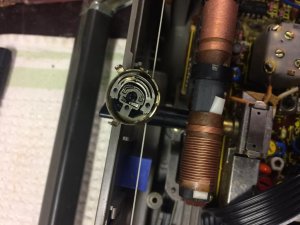

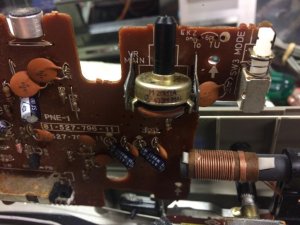

Once the box was dismantled I identified the volume pot. This is the easiest design to work on and very common.

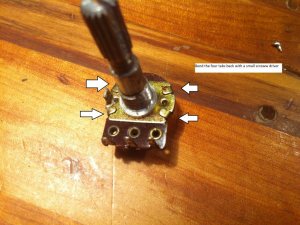

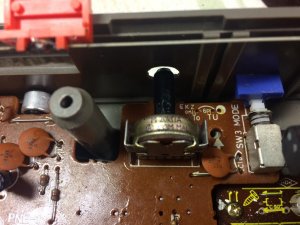

Using A small flat screw driver I bent back the four retaining tabs.

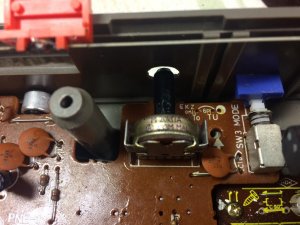

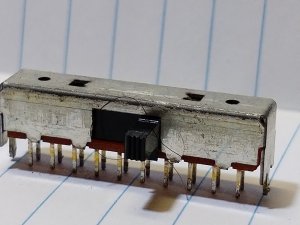

The top section will separate with the contact plate attached.

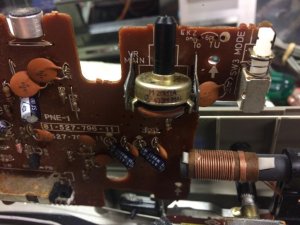

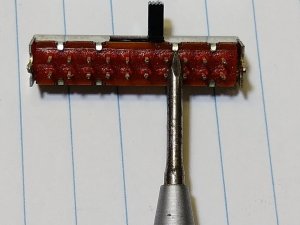

The pcb with the carbon tracks remains attached to the main board.

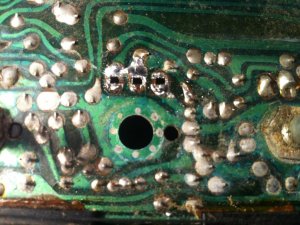

Clean all surfaces gently and apply a non conductive grease. I use silicone.

Reassemble the top and bend back the retaining tabs. Ensure you compress the tabs with plyers so you get good pressure on the contacts and pcb.

You should now have a smooth and fully functioning volume pot.

I had an Aiwa mini box that would drop a channel at low to mid volume. At full volume both channels worked fine.

Once the box was dismantled I identified the volume pot. This is the easiest design to work on and very common.

Using A small flat screw driver I bent back the four retaining tabs.

The top section will separate with the contact plate attached.

The pcb with the carbon tracks remains attached to the main board.

Clean all surfaces gently and apply a non conductive grease. I use silicone.

Reassemble the top and bend back the retaining tabs. Ensure you compress the tabs with plyers so you get good pressure on the contacts and pcb.

You should now have a smooth and fully functioning volume pot.