Someone of you knows that i spend many time in my little workshop,

and today i test a new switchdesign on my Crown CSC 850, cause some ask me if its possible to make

Aluswitches.....Or squared ones.....Its not easy but also good to make. The difficult depend on the design

of the implemented switchshafts. They are made from a strong plastic with a special design. And i solve this also.

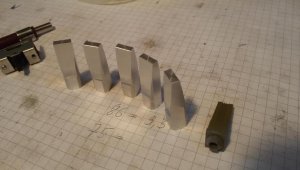

Here is my first result for the CSC 850: Looks worst on the pictures, but it isnt.....The Aluswitch has flated sides

and this avoid the turning on the switchshaft. If it was round also, cause it need a little force to push it on the shaft.

On the bottom i make nothing. It looks ok like it is. Only the felt is under the Aluknob. Maybee i think about it again

and today i test a new switchdesign on my Crown CSC 850, cause some ask me if its possible to make

Aluswitches.....Or squared ones.....Its not easy but also good to make. The difficult depend on the design

of the implemented switchshafts. They are made from a strong plastic with a special design. And i solve this also.

Here is my first result for the CSC 850: Looks worst on the pictures, but it isnt.....The Aluswitch has flated sides

and this avoid the turning on the switchshaft. If it was round also, cause it need a little force to push it on the shaft.

On the bottom i make nothing. It looks ok like it is. Only the felt is under the Aluknob. Maybee i think about it again

Attachments

-

66.3 KB Views: 9

-

64.6 KB Views: 14

-

52.9 KB Views: 6

-

37.5 KB Views: 7

-

68.8 KB Views: 7

the bigger ones are much easier than the switchtips.....

the bigger ones are much easier than the switchtips.....