Do you have the correct size pulley?

What does that have to do with this issue? Docs is saying that the pitch control is having no effect. An improper sized pulley might alter the speed but won't affect the ability to change the pitch.

docs said:

Hi Norm, I tested the ohmage of the pot at the two pins on the pot board where the wire goes to the deck board. I disconnected the cable also..

I saw it change between Oohm and 4kohm when turning the pot.

Presuming the motor is shot?

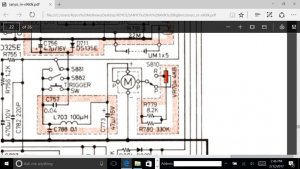

Dave, upon closer examination of the service manual, that 2-pin connector doesn't match up like you would think based on what you would presume from reading the schematic. There is S810 in between the wiper connection & the motor. s810 is the record/playback switch. Also, when you look at the PCB diagram of the board that houses the pot, that 2-pin connector is not connected directly to the wiper of the pot. Rather, the hot lead is redirected off that board to the 4-pin connector. I presume that it goes to the R/P switch then returns back to that board then to the pot wiper connection.

Additionally, based on the schematic, although one leg goes to the wiper, the other connection passes through 2 parallel resistors. If you were measuring at the leads that connects to the motor (not the + or - connections, the other 2), you should never read 0 ohms. Right?

Anyhow, yes, it's quite possible that the motor is now bad. It's seems common for 4-wire motors to go bad for some reason. They definitely seem to fail more often than traditional 2-wire motors. However you might be able to disassemble the motor and repair the little PCB that is inside there? However, before you write off that motor, I still think some more investigation needs to be done first. If it's easy enough to do, I suggest you desolder the 2 speed control wires from the motor and check resistance at those 2 wire ends. Are you again getting 0 - 4k when you rotate the pot with the 2P connection tethered? Based on the schematic, I can't seem to ignore the 2 resistors. Ribbon connections shorting is common enough. By my calculations, that parallel resistor network should equal 8001 ohms (or probably 8k intended).

Here is a test. Try disconnecting the 2 control wires. Temporarily solder those two control pads on the motor to an external pot and resistor setup to come up with a comparable resistance network. Maybe a 6.8k in series with 1.2k (to come up with 8k), and then to a 5k pot. See if that restores adjustable pitch. If yes, then the motor is OK and the problem is within either that board, or the wiring, or a short somewhere, or the R/P switch might be bad or have a shorted pin.