The motor on your tape drive can develop internal friction on the brass bushing. This can be observed by the tape transport speed sounding slow. While these motors are small they are very reliable and can be serviced. The object of the task is to ensure the shaft rotates with minimum friction while preserving the contacts.

Best to eliminate other issues first;

The motor can generally over come other friction in the drive system. Now read this tutorlal here;

http://www.instructables.com/id/repairing-a-small-DC-electric-motor/?ALLSTEPS

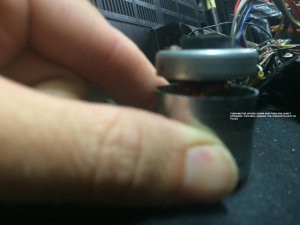

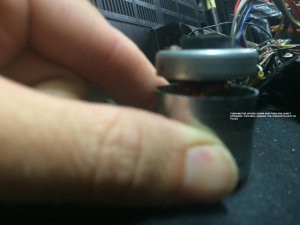

There is a more appropriate motor at the end. My tip once all cleaned re assemble the Brush Gear on the commutator ring first and then slide the casing over the rotor. This way the contacts will maintain the correct position and avoid damage. As per this pic;

I found a motor that was running slow, as it turns out there was an issue with the commutator. Here's how I fixed it;

Best to eliminate other issues first;

- Pinch roller (Replace or test with finger tip should take a fare amount of force to stop it turning)

- Rubber Belts (Replace or ensure they aren't slipping and confirm Auto Stop works)

The motor can generally over come other friction in the drive system. Now read this tutorlal here;

http://www.instructables.com/id/repairing-a-small-DC-electric-motor/?ALLSTEPS

There is a more appropriate motor at the end. My tip once all cleaned re assemble the Brush Gear on the commutator ring first and then slide the casing over the rotor. This way the contacts will maintain the correct position and avoid damage. As per this pic;

I found a motor that was running slow, as it turns out there was an issue with the commutator. Here's how I fixed it;