Over the last couple of days I've worked on a rather sad looking Toshiba RT-170S. All the usual suspects were present: spider webs, warped tuner display, gnarly ol' aerial bent in every which way, lack of function or reduced function in crackly pots & controls, dirtier than me playing in mud aged 6, A/C inlet hiding somewhere inside along with a rattle or two.

An iconic box this will never be but too good to discard and whilst there's hope in my heart and the longing to be rescued beckons, the time to once again roll up my sleeves is here.

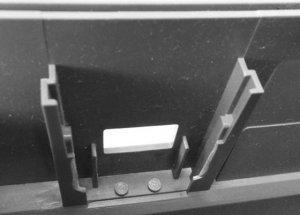

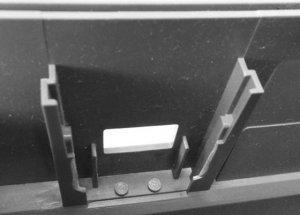

The A/C inlet socket had been knocked back into the box so this would be the first thing to check for safety reasons:

A look inside revealed the flanges had been broken off:

The A/C socket was attached to a small PWB with a screw at the other end that secured this component to a post sited on the back case:

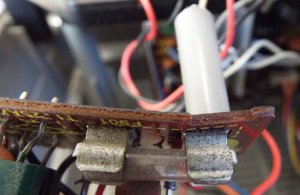

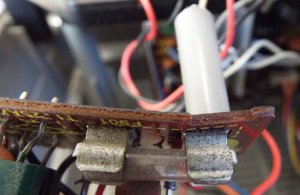

The impact that had pushed the A/C inlet into the box had also bent the PWB and sheared the post off at it's base:

First job was to fit replacement flanges in place for the A/C inlet to slide down into. These had to be thin so as not to prevent the PWB from sliding down to it's location. It was a tricky ol' job as the parts were small but Plastic Weld came to the rescue:

Plastic Weld saved the day when it was used to re-secure the mounting post. First, rotate the post into the correct location for maximum contact surface then apply Plastic Weld. Second, drill a post-size hole in each of two thick pieces of plastic, cut to size, slide one over the post and secure with Plastic Weld, repeat for the second piece of plastic profile. Result: A rock solid post. Not a pretty sight but these are basic repairs on a basic box as opposed to a more formal restoration on a Grail Box.

The PWB had a hairline crack on one surface where it had been bent so only a little pressure was needed to flatten this prior to a live test to see if it was still in working order - and it was.

I'll put some though as to how I can reinforce this PWB for added strength and to prevent warping or bending over time.

I'll put some though as to how I can reinforce this PWB for added strength and to prevent warping or bending over time.

The tuner display had warped and it's a mystery to me how this has happened. Working a thin profile knife under the nearest end to the warp lifted enough to enable me to peel back the display panel to the warp and press in back down to it's correct position. The adhesive backing to the tuner display panel seemed as strong as the day it was made which made this an easy job taking about 2 minutes:

The aerial was straightened, front case bathed, pots and moving parts serviced, deck cleaned of goo along with years of fluff & dust etc., all the usual stuff. I've yet to fit a replacement belt (I don't have one to hand at the moment - grrrr) and there are two areas of limited but nasty scratches on the top. The scratches may be something I practice filling/re-spraying on but it's not the end of the world or one of those nagging jobs-to-be-done-every-time-I-see-the-box because 'its the sort of box I'd use when gardening etc. as the box only cost me £10.50.

As I mentioned early, not a fully or formally resto'd box but repaired to bring it into use with only a deck belt now needed. Even I was surprised how well this grubby & forlorn box cleaned up:

An iconic box this will never be but too good to discard and whilst there's hope in my heart and the longing to be rescued beckons, the time to once again roll up my sleeves is here.

The A/C inlet socket had been knocked back into the box so this would be the first thing to check for safety reasons:

A look inside revealed the flanges had been broken off:

The A/C socket was attached to a small PWB with a screw at the other end that secured this component to a post sited on the back case:

The impact that had pushed the A/C inlet into the box had also bent the PWB and sheared the post off at it's base:

First job was to fit replacement flanges in place for the A/C inlet to slide down into. These had to be thin so as not to prevent the PWB from sliding down to it's location. It was a tricky ol' job as the parts were small but Plastic Weld came to the rescue:

Plastic Weld saved the day when it was used to re-secure the mounting post. First, rotate the post into the correct location for maximum contact surface then apply Plastic Weld. Second, drill a post-size hole in each of two thick pieces of plastic, cut to size, slide one over the post and secure with Plastic Weld, repeat for the second piece of plastic profile. Result: A rock solid post. Not a pretty sight but these are basic repairs on a basic box as opposed to a more formal restoration on a Grail Box.

The PWB had a hairline crack on one surface where it had been bent so only a little pressure was needed to flatten this prior to a live test to see if it was still in working order - and it was.

I'll put some though as to how I can reinforce this PWB for added strength and to prevent warping or bending over time.

I'll put some though as to how I can reinforce this PWB for added strength and to prevent warping or bending over time.The tuner display had warped and it's a mystery to me how this has happened. Working a thin profile knife under the nearest end to the warp lifted enough to enable me to peel back the display panel to the warp and press in back down to it's correct position. The adhesive backing to the tuner display panel seemed as strong as the day it was made which made this an easy job taking about 2 minutes:

The aerial was straightened, front case bathed, pots and moving parts serviced, deck cleaned of goo along with years of fluff & dust etc., all the usual stuff. I've yet to fit a replacement belt (I don't have one to hand at the moment - grrrr) and there are two areas of limited but nasty scratches on the top. The scratches may be something I practice filling/re-spraying on but it's not the end of the world or one of those nagging jobs-to-be-done-every-time-I-see-the-box because 'its the sort of box I'd use when gardening etc. as the box only cost me £10.50.

As I mentioned early, not a fully or formally resto'd box but repaired to bring it into use with only a deck belt now needed. Even I was surprised how well this grubby & forlorn box cleaned up:

This box looks like it´s low-end average-sounding one but actually it´s quite of a box, really, sounds just great to me

This box looks like it´s low-end average-sounding one but actually it´s quite of a box, really, sounds just great to me  Good job, good job

Good job, good job