Hi all,

I'm working on an Hitachi TRK-8600E at the moment (more of this on another thread) and I've a problem with a noisy tape deck. I say 'a problem' but I fell There may be two separate issues here.

This first video is the sound the deck made upon receipt, the longer the box is left switched on, the louder and different the noise became. No tape deck controls were in use and no tape was in the tape deck, all I did was turn the power on (function switch pre-set to 'Radio' for demonstration purposes only).

Camera is held close to record the sound:

https://vimeo.com/147848147

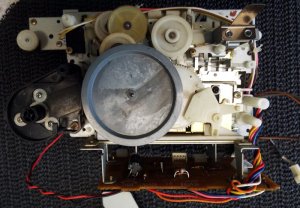

I opened the box, gave the tape deck a clean, replaced four belts:

1 X square counter belt

1 X flat flywheel belt

2 X other square belts

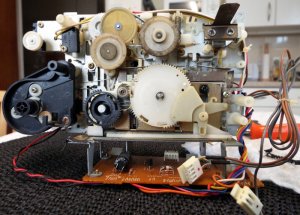

I closed the box but a different noise is now coming from the deck. This noise is a mechanical grinding/scraping noise sounding (to my somewhat untrained ears) as if the flywheel is scraping on the cover plate as it rotates or something very similar. Everything seemed fine when I reassembled the deck and box. The noise is the same when a tape is set to 'Play' or when there is no tape in the deck. Notice, also, that when either FF or RW buttons are pressed they do not stay down. The playback head & mechanism lifts as it should when 'Play' is pressed:

https://vimeo.com/147848960

Can anyone throw any light on this before I open up the box again, please? I'll check the rotary motion of the flywheel to see if there's any contact with another surface but I don't know what else to look for at this point.

I used belts from a 'bulk pack' and fitted belts that I felt to be the correct size. I have to consider that one or more of the belts I fitted may not be absolutely the correct size but I've never made a mistake yet on any of the several boxes I've rebelted so far.

I'm working on an Hitachi TRK-8600E at the moment (more of this on another thread) and I've a problem with a noisy tape deck. I say 'a problem' but I fell There may be two separate issues here.

This first video is the sound the deck made upon receipt, the longer the box is left switched on, the louder and different the noise became. No tape deck controls were in use and no tape was in the tape deck, all I did was turn the power on (function switch pre-set to 'Radio' for demonstration purposes only).

Camera is held close to record the sound:

https://vimeo.com/147848147

I opened the box, gave the tape deck a clean, replaced four belts:

1 X square counter belt

1 X flat flywheel belt

2 X other square belts

I closed the box but a different noise is now coming from the deck. This noise is a mechanical grinding/scraping noise sounding (to my somewhat untrained ears) as if the flywheel is scraping on the cover plate as it rotates or something very similar. Everything seemed fine when I reassembled the deck and box. The noise is the same when a tape is set to 'Play' or when there is no tape in the deck. Notice, also, that when either FF or RW buttons are pressed they do not stay down. The playback head & mechanism lifts as it should when 'Play' is pressed:

https://vimeo.com/147848960

Can anyone throw any light on this before I open up the box again, please? I'll check the rotary motion of the flywheel to see if there's any contact with another surface but I don't know what else to look for at this point.

I used belts from a 'bulk pack' and fitted belts that I felt to be the correct size. I have to consider that one or more of the belts I fitted may not be absolutely the correct size but I've never made a mistake yet on any of the several boxes I've rebelted so far.