Hello All-

[SIZE=14pt]My Telefunken Studio 1M cassette deck plays/FF/RR very slowly. I opened her up which took some time (if anyone wants specific photos please ask) and have had a look. Here are some questions I have...which should help me have her up and running!![/SIZE]

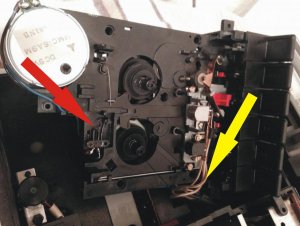

[SIZE=14pt]1. My pinch roller may be dirty and no good (see photo). I will try to clean first and see if that helps. If I need to order a new one, can I just measure the dimensions and buy off Ebay? Any other places to buy with a better selection?[/SIZE]

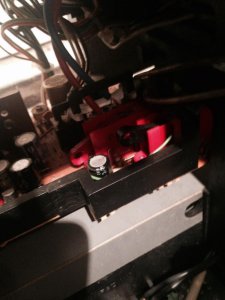

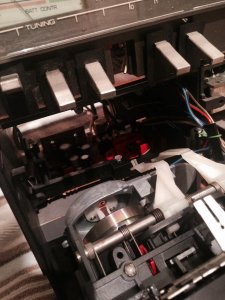

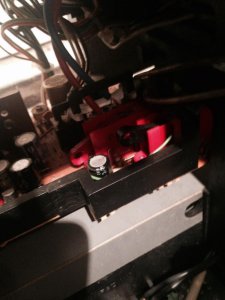

[SIZE=14pt]2. I can't tell if the capstan motor has speed adjustment (see photo). There is a small hole (~1/8" diameter, ~1/4" deep) with a plastic sheet over it. I can drop a jeweler phillips head or allen key through this shet. I tried different sizes and nothing seemed to "catch". Does it even look like that is for speed adjustment (theres nothing else)? What type of bolt is typical for motor speed adjustment? Bonus: do you know what I need for my specific model?[/SIZE]

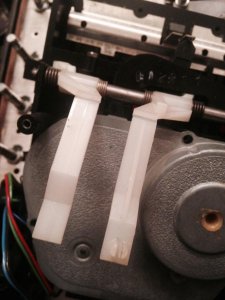

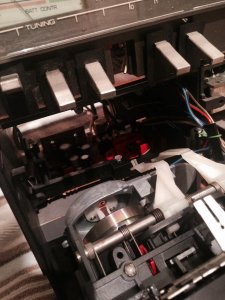

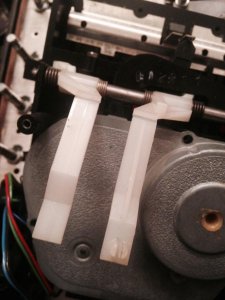

[SIZE=14pt]3.There are these two plastic (semi-transparent) "columns" connected to the deck. They connect into the board behind the deck (see last few pictures). I forgot to take a photo of this before I disassembled...which is why I'm in trouble. They unhooked very easily (at the lower tip of this plastic). The attached photos show (1) the plastic pieces, and (2) photos attempting to show where they connect to. Any help here is appreciated![/SIZE]

[SIZE=14pt]FYI..I don't think its the belt. I ordered a new belt kit and the drive belt is maybe 3-5% smaller. I don't think the old belt was loose.[/SIZE]

[SIZE=14pt]Thanks as Always![/SIZE]

[SIZE=14pt]My Telefunken Studio 1M cassette deck plays/FF/RR very slowly. I opened her up which took some time (if anyone wants specific photos please ask) and have had a look. Here are some questions I have...which should help me have her up and running!![/SIZE]

[SIZE=14pt]1. My pinch roller may be dirty and no good (see photo). I will try to clean first and see if that helps. If I need to order a new one, can I just measure the dimensions and buy off Ebay? Any other places to buy with a better selection?[/SIZE]

[SIZE=14pt]2. I can't tell if the capstan motor has speed adjustment (see photo). There is a small hole (~1/8" diameter, ~1/4" deep) with a plastic sheet over it. I can drop a jeweler phillips head or allen key through this shet. I tried different sizes and nothing seemed to "catch". Does it even look like that is for speed adjustment (theres nothing else)? What type of bolt is typical for motor speed adjustment? Bonus: do you know what I need for my specific model?[/SIZE]

[SIZE=14pt]3.There are these two plastic (semi-transparent) "columns" connected to the deck. They connect into the board behind the deck (see last few pictures). I forgot to take a photo of this before I disassembled...which is why I'm in trouble. They unhooked very easily (at the lower tip of this plastic). The attached photos show (1) the plastic pieces, and (2) photos attempting to show where they connect to. Any help here is appreciated![/SIZE]

[SIZE=14pt]FYI..I don't think its the belt. I ordered a new belt kit and the drive belt is maybe 3-5% smaller. I don't think the old belt was loose.[/SIZE]

[SIZE=14pt]Thanks as Always![/SIZE]