Hey all,

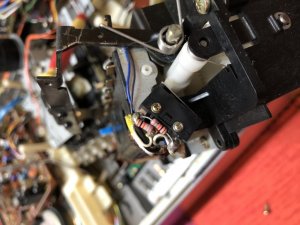

I am working on a TPR-990 & the radio/line in works ok. The radio sounds good & powerful, no issues but the deck is dead. The flywheel motor is fine & you can hear it clicking but the carriage is stuck, almost engaged but, not quite enough to start the wheels turning, so to speak. If I lift the carriage the last 2-3mm to engage the pinch-roller to the flywheel pin, everything starts moving & I bet I could hear the tape if I could fit one in there. The Play LED & Pause LED are lit & I hear a click, every few seconds like something wants to engage or release, etc.

Plus, all of the buttons for the cassette on the front are stiff, as if they can't move at all....even pause & stop....

Any ideas?

Cpl

I am working on a TPR-990 & the radio/line in works ok. The radio sounds good & powerful, no issues but the deck is dead. The flywheel motor is fine & you can hear it clicking but the carriage is stuck, almost engaged but, not quite enough to start the wheels turning, so to speak. If I lift the carriage the last 2-3mm to engage the pinch-roller to the flywheel pin, everything starts moving & I bet I could hear the tape if I could fit one in there. The Play LED & Pause LED are lit & I hear a click, every few seconds like something wants to engage or release, etc.

Plus, all of the buttons for the cassette on the front are stiff, as if they can't move at all....even pause & stop....

Any ideas?

Cpl