Body Work: GF 8989z

- Thread starter Lasonic TRC-920

- Start date

Lookin good Chris! I was wondering what all was up your sleeve on this repair..? Are you thinking of fusing all the peices together with JB weld putty?

The pride in fixing something like this pays off every time u pick up this blaster and put it to use!

The pride in fixing something like this pays off every time u pick up this blaster and put it to use!

Solid looking repair Chris. Sort of like a Robocop repair! That corner of the box will 10 times stronger than factory.

Nice one.

James...

Nice one.

James...

Hey Guys....

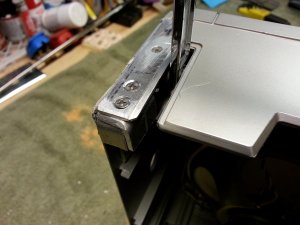

The plan is to capture the handle inside mounting points and then distribute the load back to the top and sides.

I layered the area where the hole was building it up with 3 pieces of aluminum. I was going to drill and screw that together. I was also going to look for machined hardware that I can counter sink into the side wall in 4 places. I may not need to put any screws in the top, but it is still an option. Then I was going to screw and bond the plate flat to the side wall.

I can already tell that the load will hold the radios weight.

After all that, I will use bondo to fill in and shape the out side. I have some work to do to repair a bit on the rear case near the handle, then paint!

The plan is to capture the handle inside mounting points and then distribute the load back to the top and sides.

I layered the area where the hole was building it up with 3 pieces of aluminum. I was going to drill and screw that together. I was also going to look for machined hardware that I can counter sink into the side wall in 4 places. I may not need to put any screws in the top, but it is still an option. Then I was going to screw and bond the plate flat to the side wall.

I can already tell that the load will hold the radios weight.

After all that, I will use bondo to fill in and shape the out side. I have some work to do to repair a bit on the rear case near the handle, then paint!

Solid design and awesome craftsmanship.

The repair will hold the weight, the pictures itself tell that.

The repair will hold the weight, the pictures itself tell that.

Thanks guys...

Today I'm hoping to get everything screwed and bonded in place. I have a 2 part epoxy called "Super Mend" that I will use to bond the aluminum plate to the side and top of the radio. I will also use it to bond the 3 aluminum plates together. Then I will start shaping and filling with bondo.

Today I'm hoping to get everything screwed and bonded in place. I have a 2 part epoxy called "Super Mend" that I will use to bond the aluminum plate to the side and top of the radio. I will also use it to bond the 3 aluminum plates together. Then I will start shaping and filling with bondo.

awesome job man, you know what works great for filling holes like that is the jb weld type putty that you knead and press into place .i use that stuff a lot and it works great . the trick to it is to shave off the excess material before it hardens then you only have finish sanding to do once it hardens .

I have used JB many times...in fact they have a great 2 part mix especially for exhaust manifolds. Works great.JVC Floyd said:awesome job man, you know what works great for filling holes like that is the jb weld type putty that you knead and press into place .i use that stuff a lot and it works great . the trick to it is to shave off the excess material before it hardens then you only have finish sanding to do once it hardens .

The Super Mend I have can also be sanded and drilled.

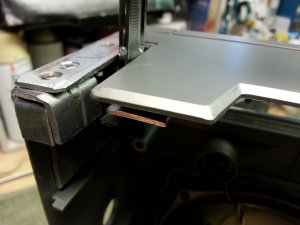

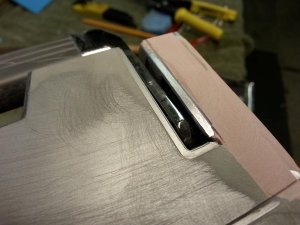

Here are some more pictures...I have all the machine work done.

Here you can see where I filed in a lip to match the factory line on the other side of the handle bracket.

Here all the holes are drilled and countersunk, sandwiching all the pieces together. This ties the handle mount in firmly to support the weight of the radio.

The top of the metal is now at the top level of the radio, so just minimum body filler will be needed.

Very impressive!...these corner repairs are super fiddly because of all the different angles and corners. Add to that the fact that this is weight bearing too makes it even trickier. There's a lot of time gone into this. So satisfying when it's all done...keep up the good work!

This is the art of repairing..

I am impatient to see the final result..

Chris, I'm sure you could get a job at any time as a master in any auto body repair shop..

I am impatient to see the final result..

Chris, I'm sure you could get a job at any time as a master in any auto body repair shop..

Excellent stuff!...I'm sure you probably know but just be aware that any imperfection on like the edges or corners that look acceptable now may not once painted as it shows up much more once painted. I'd be putting a little filler where the little imperfections are on the edges and resanding

No doubt about it, you gotz skillz. Very good job so far. I was kinda hoping for the robocop/blaster look but this will be minty!!

If only my bad back could handle leaning over the fender of a car all day.devol-toni said:This is the art of repairing..

I am impatient to see the final result..

Chris, I'm sure you could get a job at any time as a master in any auto body repair shop..

Oh yeah....it will be much nicer before we get to painting...Northerner said:Excellent stuff!...I'm sure you probably know but just be aware that any imperfection on like the edges or corners that look acceptable now may not once painted as it shows up much more once painted. I'd be putting a little filler where the little imperfections are on the edges and resanding

It's coming along. I probably have 15 hours in it already.blu_fuz said:Holy shiat that's awesome!

k2j said:No doubt about it, you gotz skillz. Very good job so far. I was kinda hoping for the robocop/blaster look but this will be minty!!

! Chris that is going to turn out NICE

! Chris that is going to turn out NICE